PKG 1P Plastic Airtight Pneumatic / Fluidic Medical Socket

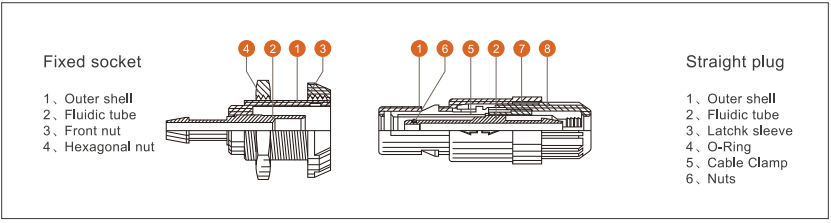

The PKG 1P Plastic Airtight Pneumatic / Fluidic Medical Socket is purpose-built for demanding environments such as hospital-grade devices, lab analyzers, and automated pneumatic systems. Inspired by the LEMON REDEL series, this connector integrates airtight fluidic channels within a self-latching push-pull mechanism, ensuring both fast operation and safe disconnection under pressure.

Constructed from biocompatible PPSU or medical-grade PBT, the housing resists sterilization by autoclave, ETO, and gamma radiation. The PKG 1P socket supports up to 2 bar fluidic or pneumatic pressure, while its precision-machined collet ensures tight tube retention and repeatable, sterile performance.

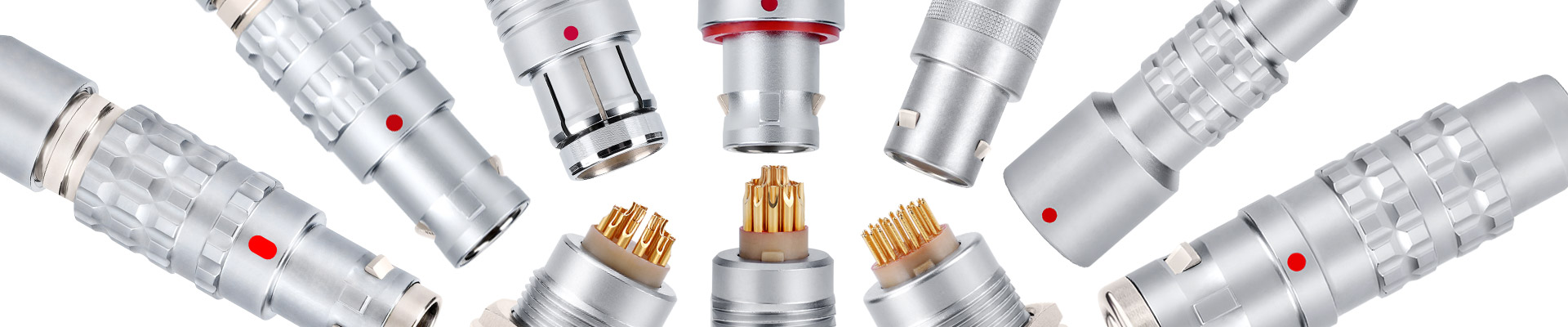

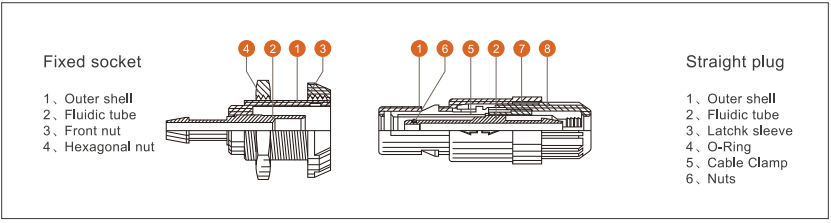

Plastic medical connectors Overview

| Straight plastic plug | fixed socket

| Free socket |

|

|

|

PAG M0 1P plastic plug | ERA socket nut fixing | PRG Free socket,cable collet |

|

|

|

PAG M0 1P plastic plug | PKG nut fixing | PRG Free socket,cable collet with bend relief |

| Fluidic configuration |

Key Features

Push-pull self-latching for one-hand quick connect/disconnect

Airtight fluidic and pneumatic path design, ideal for oxygen, vacuum, or diagnostic use

Housing options: PPSU or PBT for medical compliance and sterilization resistance

Mates with matching plastic plugs to create a sealed pneumatic interface

Supports single fluidic channel or customizable hybrid configurations

Optional color-coded caps for intuitive identification in multi-channel setups

Whether for single-use or reusable systems, PKG 1P offers the reliability, cleanliness, and ergonomic ease expected in modern medical and laboratory environments.

Fluidic Socket Applications

The PKG 1P is widely used in pneumatic control systems in industrial automation equipment, gas and fluid management in medical devices, and fluid control and testing setups in laboratories. With its high reliability and flexibility, the PKG 1P is the ideal connector choice for meeting diverse application needs

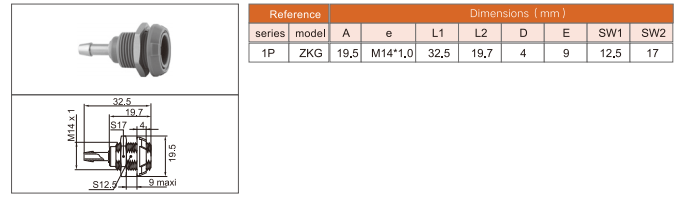

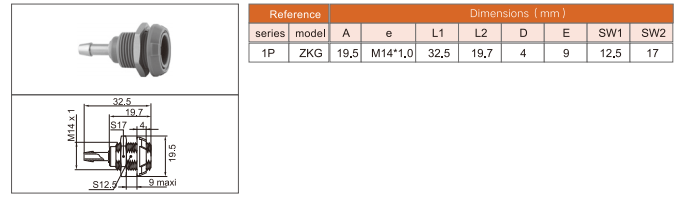

PKG 1P Plastic Airtight Pneumatic / Fluidic Socket Diamensions

How to Select PKG 1P Fluidic Plastic medical airtight pneumatic socket

When selecting a PKG 1P plastic airtight socket, consider the following key factors to ensure compatibility and optimal performance:

Medical socket Tube Size Compatibility – Choose according to the fluidic tubing’s OD/ID (6mm × 2.6mm) to ensure a secure and leak-free fit.

Medical socket Connection Type – These sockets use quick-disconnect push-pull design, making them suitable for frequent connection/disconnection in medical environments.

Material Requirements – The plastic material provides lightweight, sterilizable, and corrosion-resistant performance for medical applications.

Application Environment – Select models designed for diagnostic devices, surgical tools, or modular fluidic systems, depending on your specific need.

Integration with P Series – Ensure compatibility with Lemo P series 1P pneumatic socket for seamless upgrades or replacements.

PKG 1P Fluidic Plastic Socket Selection

| Parameter | PKG.A01.UGL.LA | PKG.A01.AGL.LA | PKG.A01.GGL.LA | PKG.A01.LGL.LA | PKG.A01.SGL.LA | PKG.A01.TGL.LA | PKG.A01.GZL LZ |

| Tube Size | OD 6mm × ID 2.6mm Fluidic airtight socket | OD 6mm × ID 2.6mm Fluidic airtight socket | OD 6mm × ID 2.6mm Fluidic airtight socket | OD 6mm × ID 2.6mm Fluidic airtight socket | OD 6mm × ID 2.6mm Fluidic airtight socket | OD 6mm × ID 2.6mm Fluidic airtight socket | OD 6mm × ID 2.6mm Fluidic airtight socket |

| Type | Fluidic quick-disconnect socket | Fluidic quick-disconnect socket | Fluidic quick-disconnect socket | Fluidic quick-disconnect socket | Fluidic quick-disconnect socket | Fluidic quick-disconnect socket | Fluidic quick-disconnect socket |

| Description | Airtight airtight socketor single-fluid tube connection, reliable for fluidic quick-disconnect systems | Compact pneumatic socket designed for easy integration with medical fluid transfer devices | Durable pneumatic socket medical applications | High-precision plastic quick-connect socket for fluidic medical systems | Robust plastic socket optimized for indoor medical environments | Secure pneumatic quick-disconnect socket for healthcare fluidic modules | Advanced airtight socket compatible with modular medical fluidic devices |

| Application | plastic socket Used in medical fluid transfer, diagnostic devices, and lab instruments | plastic socket For hospital pneumatic socket systems and modular medical equipment | pneumatic socket Suitable for quick fluidic coupling in surgical tools | plastic socket Applied in clinical diagnostic machines and patient-care systems | pneumatic socket For fluid transfer modules in therapeutic devices | plastic socket Used in sterilizable fluidic connections for medical labs | pneumatic socket Applied in complex modular medical pneumatic socket systems |

| Contacts |  |

Medical Socket Technical characteristics

| Characteristics | Values |

|---|

| Mating cycles | >1000 cycles |

| Maximum working pressure | 2 bars |

| Series | P SERIES-1P PAG Socket |

| Working Temperature | -40°C / +120°C |

| Humidity | Up to 95% at 60°C |

| Rated voltage | 200–400V |

| Working current | 2–10A |

| IP Rating (when mated) | IP50 |

| Characteristics | Values |

|---|

| Internal fluid diameter | 2.6 mm |

| Inner/outer tube diameter | 4 mm / 6 mm |

| Fluid tube material | Nickel plated Brass |

| O-Ring Material | FPM |

| Leakage rate | When the air pressure difference is 400 mmHg, |

Why Choose LINKHIVE?

1.Fast Delivery & Global Shipping for airtight socket

We maintain ample stock of PKG 1P plastic pneumatic socket and guarantee 2-week lead times for bulk orders. With a reliable logistics network, we provide fast worldwide shipping, ensuring on-time delivery for urgent medical and laboratory projects.

2.Plastic socket In-House R&D Expertise

Our dedicated R&D team continuously develops advanced fluidic and pneumatic socket solutions, optimizing leak-proof performance and medical-grade safety. We collaborate with healthcare institutions to provide customized connector designs for complex diagnostic and therapeutic systems.

3.Manufacturing Excellence of medical socket

All medical socket are manufactured in our state-of-the-art factory in China, using precision molding and assembly processes. Our production lines follow medical device quality standards, ensuring that every connector meets stringent medical and industrial requirements.

Direct manufacturer – Competitive pricing with no middleman.

Medical-grade quality – Designed for diagnostic, surgical, and fluidic systems.

Global support – Export experience to Europe, North America, and Asia.

Customizable solutions – Tailor-made connectors for your project needs.