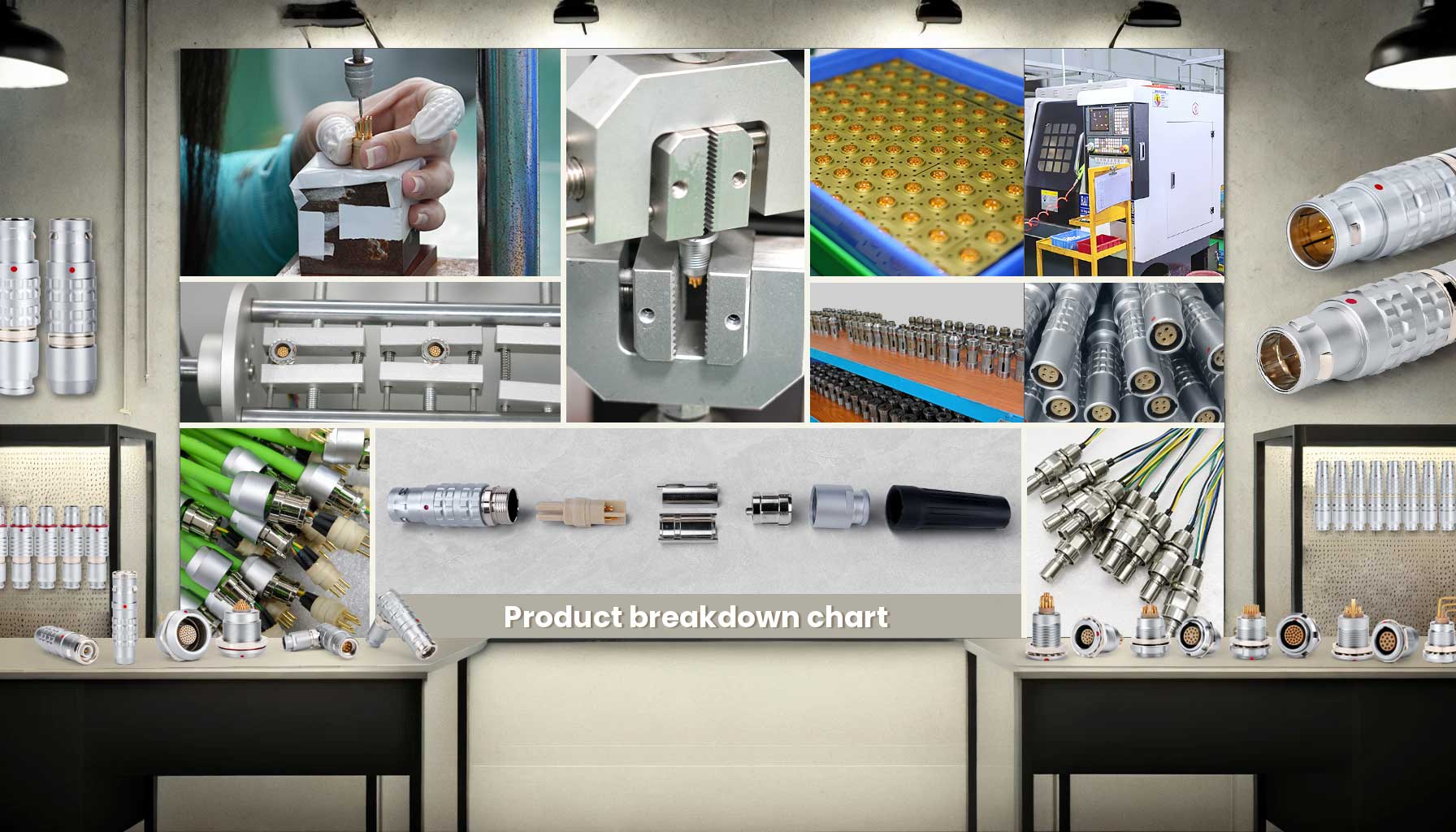

Advanced Connector Manufacturing Equipment at LINKHIVE

LINKHIVE is equipped with a set of advanced production equipment that enables us to efficiently manufacture a wide variety of connectors, ensuring both precision and quality. Our production equipment covers all aspects of manufacturing, from metal component processing to plastic part molding, meeting the highest production standards. The equipment includes 10 automatic lathes, 3 imported horizontal Swiss-type lathes, 5 imported vertical Swiss-type lathes, 8 injection molding machines, 2 grinding machines, 2 milling machines, and 2 EDM machines.

First, the automatic lathes are key to our connector production. We have 10 automatic lathes, which are used for efficiently processing metal components, especially for mass production of precision parts. These lathes maintain high precision while performing fast cutting, ensuring that each part meets strict dimensional and tolerance standards. This high production efficiency greatly increases our factory's output, allowing us to deliver large orders on time.

LINKHIVE is equipped with a set of advanced production equipment that enables us to efficiently manufacture a wide variety of connectors, ensuring both precision and quality. Our production equipment covers all aspects of manufacturing, from metal component processing to plastic part molding, meeting the highest production standards. The equipment includes 10 automatic lathes, 3 imported horizontal Swiss-type lathes, 5 imported vertical Swiss-type lathes, 8 injection molding machines, 2 grinding machines, 2 milling machines, and 2 EDM machines.

First, the automatic lathes are key to our connector production. We have 10 automatic lathes, which are used for efficiently processing metal components, especially for mass production of precision parts. These lathes maintain high precision while performing fast cutting, ensuring that each part meets strict dimensional and tolerance standards. This high production efficiency greatly increases our factory's output, allowing us to deliver large orders on time.

In addition, LINKHIVE is equipped with 3 imported horizontal Swiss-type lathes. These lathes are highly precise CNC machines, ideal for processing complex parts. Horizontal Swiss-type lathes can perform multiple machining operations simultaneously, improving production efficiency while maintaining machining accuracy. The addition of these machines enables us to produce more intricate connector components, catering to the diverse needs of our customers.

We also have 5 imported vertical Swiss-type lathes. The advantage of vertical lathes is that they can perform vertical machining, which is especially useful for producing components with complex geometric shapes. By combining vertical and horizontal lathes, we can offer more flexible production solutions, ensuring that we efficiently produce connector components of varying complexity.

For plastic component manufacturing, LINKHIVE is equipped with 8 injection molding machines. These machines inject molten plastic into molds to produce complex shapes for plastic connector housings and parts. The high efficiency of these machines not only speeds up the production of plastic components but also ensures consistent quality. Our injection molding equipment allows us to manufacture plastic parts in a wide range of sizes and applications for different types of connectors.

In addition to the main equipment mentioned above, we also have 2 grinding machines and 2 milling machines, which are used for the fine machining of metal components. The grinding machines ensure the smoothness and precision of metal surfaces, while the milling machines are used for cutting and shaping parts, allowing for precise manufacturing of complex shapes. The combination of grinding and milling machines further enhances the overall quality of our connector components.

Lastly, the 2 EDM machines (Electrical Discharge Machines) play a crucial role in our mold manufacturing. EDMs use electrical discharges to process metal materials, enabling us to create intricate mold shapes and fine details. This technology provides us with greater flexibility in mold manufacturing, ensuring precision and efficiency in the production of molds.

In summary, LINKHIVE’s advanced equipment allows us to efficiently produce high-precision, high-quality connector products. We continue to optimize our production processes and maintain cutting-edge equipment to provide our customers with superior products and services.