LINKHIVE Connector Quality Assurance

A Deep Dive into High-Precisision Testing Equipment

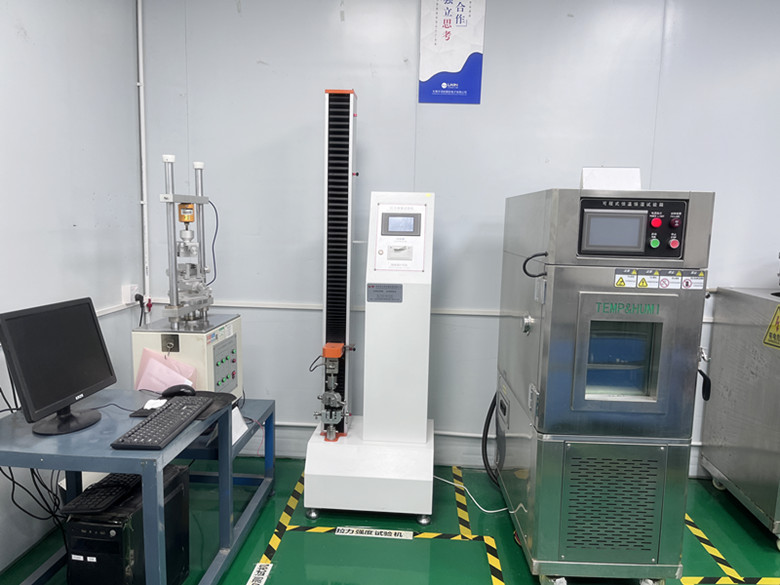

Our factory is equipped with a wide range of precision testing equipment to ensure that our products meet the highest standards across various technical parameters. These capabilities guarantee stability and durability in all application scenarios.

Precision Testing Equipment

· Insertion/Withdrawal Test Machine: This machine tests the number of insertions and withdrawals a connector can withstand, ensuring that the product maintains excellent electrical and mechanical performance after repeated use.

· Bending Test Machine: Used to assess the durability of cables under repeated bending, simulating real-world conditions where cables may experience twisting and swinging, and evaluating their mechanical strength.

· Deep Water Pressure Testing: Designed for products used in underwater environments, this test simulates the conditions of deep water to evaluate the sealing and functionality of connectors under high-pressure conditions.

· Constant Temperature Test Chamber: This chamber tests the performance of products under extreme temperature conditions, ensuring their stability in both high and low-temperature environments.

· DC High Voltage Tester: Used for testing high-voltage connectors under direct current, verifying their insulation and voltage endurance to ensure safety in high-voltage applications.

· Network Tester: This device tests the network performance of communication connectors, ensuring stability and reliability in data transmission.

· DC/AC Tester: Capable of testing products under both direct current (DC) and alternating current (AC) conditions, evaluating their electrical performance across different power environments.

· Air Tightness Tester: This tester checks the air-tightness of products, ensuring reliable sealing in environments that require waterproof and dustproof standards.

Precision Measuring Instruments

· Calipers, Micrometers, Height Gauges: These instruments are used to precisely measure the dimensions of products, ensuring that each item meets strict tolerance requirements.

· 2D Optical Projector: Utilizing optical projection technology, this instrument provides high-precision analysis of the dimensions and shapes of products.

· Coating Thickness Gauge: This device measures the thickness of surface coatings, ensuring that the product has sufficient corrosion resistance and surface treatment quality.

· Comprehensive Wire Testing Machine: Used to test the electrical and mechanical performance of wires, ensuring their stability in a wide range of applications.

Environmental and Physical Testing

· Salt Spray Tester: Simulates a salt spray environment to test the corrosion resistance of products, ensuring durability in harsh conditions.

· Tensile Strength Tester: Measures the mechanical strength of products, particularly the load-bearing capacity of cables and connectors under tension.

With these testing capabilities, our factory ensures that every product undergoes rigorous quality control, meets international standards, and can satisfy the demands of various application fields

At LINKHIVE, our test laboratory plays a crucial role in upholding our reputation for delivering precision-engineered connectors and cables across various industries, including medical devices, military applications, industrial automation, and telecommunications. The lab's primary objective is to ensure that every product undergoes rigorous evaluation, guaranteeing that it meets and exceeds industry standards for reliability, safety, and performance

Comprehensive Product Testing

Our laboratory is equipped to test a wide range of connectors and cables, including high-performance circular connectors, high-voltage connectors, waterproof connectors, and coaxial connectors. Each product undergoes a series of evaluations tailored to its specific application. For example, connectors used in the medical industry are tested for their ability to maintain reliable electrical connections under demanding conditions, including sterilization and frequent handling. Products designed for aerospace and military applications are subjected to tests that simulate extreme environmental conditions, such as high temperatures, shock, and vibration.

Our high-quality molding cable assemblies, used in the automotive and robotics industries, undergo durability testing to ensure they can withstand repetitive movement, mechanical stress, and harsh environmental conditions. By simulating real-world scenarios, we verify that these products maintain consistent performance throughout their operational lifespan.

Custom Testing for Unique Solutions

Since LINKHIVE offers customized solutions, our laboratory also conducts bespoke testing tailored to the specific requirements of our clients. This ensures that even unique designs, including hybrid connectors or connectors used in specialized machinery, perform according to stringent client specifications.

Industry Certifications and Standards

We take pride in adhering to international standards such as ISO9001:2015, CE, UL, RoHS, and GJB9001C-2019. The laboratory’s meticulous testing process ensures compliance with these certifications, providing clients across industries with the confidence that our products meet the highest quality standards. Furthermore, our laboratory supports extensive testing for connectors destined for safety-critical applications, where failure is not an option.

Focus on Innovation and Quality Assurance

As part of our commitment to innovation, we continuously update our testing procedures to align with emerging technologies and market needs. Every product from LINKHIVE is a result of this relentless pursuit of quality, backed by our advanced testing capabilities. This enables us to provide industry-leading solutions, from M-series connectors to miniature camera connectors, delivering reliability and precision across all sectors.

At LINKHIVE, we don’t just meet industry standards — we push beyond them, ensuring that every product delivered to our clients is tested for peak performance in real-world applications.