Comprehensive Connector Production: Machining, Assembly, and Molding

INKHIVE is committed to providing high-quality connector products and services to our customers, and our success is built on our outstanding performance in areas such as office environment, technological research and development, and team building.

Office Environment: LINKHIVE boasts modern office facilities and elegant workspaces. Our office building is located in a scenic area, offering a comfortable environment that fosters an open, innovative, and efficient work atmosphere. Each office is equipped with state-of-the-art equipment and technical support, ensuring that employees can work efficiently in a comfortable setting.

Technological Research and Development: LINKHIVE is always at the forefront of the industry in terms of technology. We have a dedicated R&D team composed of experienced engineers and technical experts who continuously explore new technologies and solutions to enhance product performance and meet the specific needs of our customers. The company invests heavily in technological innovation and equipment upgrades every year, ensuring our products consistently meet international standards and boast superior quality and reliability.

Our Team: Our team is LINKHIVE's most valuable asset. The company brings together professionals from various regions, and our team members not only possess rich industry experience but also have a proactive spirit and innovative mindset. We encourage continuous learning and growth among our employees, offering various training and development opportunities to help them enhance their skills and realize their potential. At the same time, the company promotes a culture of open communication and teamwork, valuing every employee's opinions and suggestions, which strengthens our team cohesion and efficiency.

At LINKHIVE, we always adhere to the principle of "customer-centricity," continuously enhancing our capabilities and innovation to provide high-quality connector products and services to customers worldwide. We firmly believe that with the concerted efforts of all our employees, LINKHIVE will continue to maintain a leading position in the international market and make even greater contributions to the industry's development.

Engineer team

Human resources

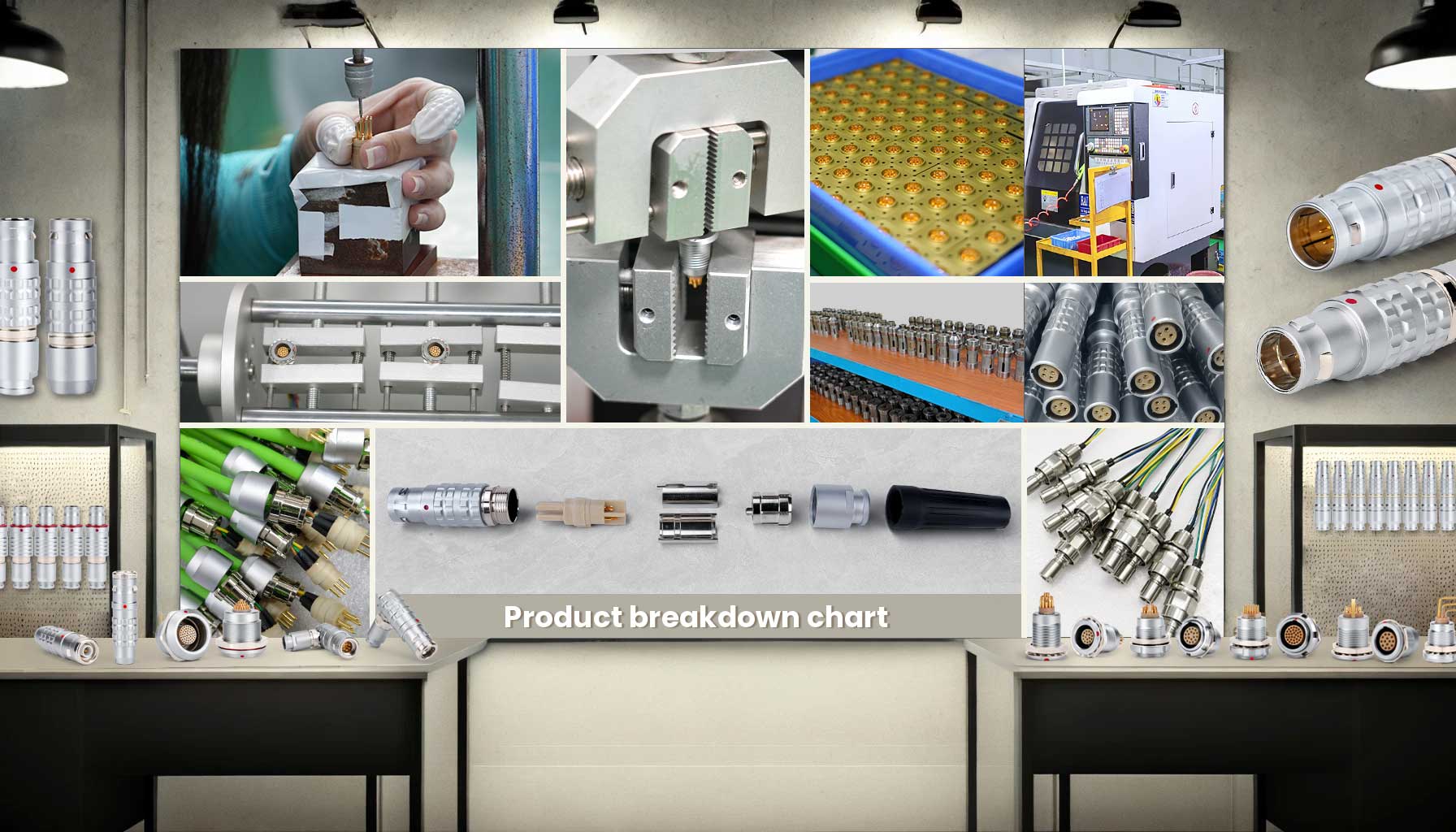

Precision and Handcraftsmanship in LINKHIVE's Connector Assembly Line

At LINKHIVE, our connector assembly line blends advanced technology with skilled manual craftsmanship to ensure exceptional quality. While automation plays a key role in certain processes, the majority of our assembly work is performed by highly trained technicians who bring precision and attention to detail to every product. From intricate soldering to the careful alignment of components, each connector is assembled with expert hands. This combination of manual craftsmanship and rigorous quality control allows us to produce reliable and durable connectors, including our B Series, S Series, and Push-Pull connectors, tailored to meet the high standards of industries like semiconductors, medical devices, and telecommunications.

Expert Handcrafted Wiring Harness Assembly Line at LINKHIVE

At LINKHIVE, our wiring harness assembly line is driven by skilled craftsmanship and meticulous attention to detail. While some processes are automated, the majority of the work is performed by our experienced technicians. Each wiring harness is carefully assembled by hand, ensuring precise connections and optimal performance. From cutting and crimping to soldering and final inspection, our technicians handle every step with expertise. This manual approach allows us to tailor solutions for complex and custom wiring needs across industries like automotive, medical, and industrial equipment. With strict quality control and a commitment to excellence, our wiring harnesses meet the highest standards of reliability and durability.

High-Precision Connector Machining Line at LINKHIVE

At LINKHIVE, our high-precision connector machining line is equipped with advanced technology to produce a wide variety of connector components with exceptional accuracy and quality. The production line includes automatic lathes, Swiss-type lathes (both horizontal and vertical), milling machines, and EDM machines, all designed to handle complex metal component processing. With 10 automatic lathes, 3 imported horizontal Swiss-type lathes, and 5 imported vertical Swiss-type lathes, we ensure high-speed production without compromising on precision. Our skilled technicians work with these machines to produce connectors that meet strict industry standards. This machining line supports various industries, including aerospace, medical, telecommunications, and more, enabling LINKHIVE to deliver reliable, high-performance connector solutions to customers worldwide