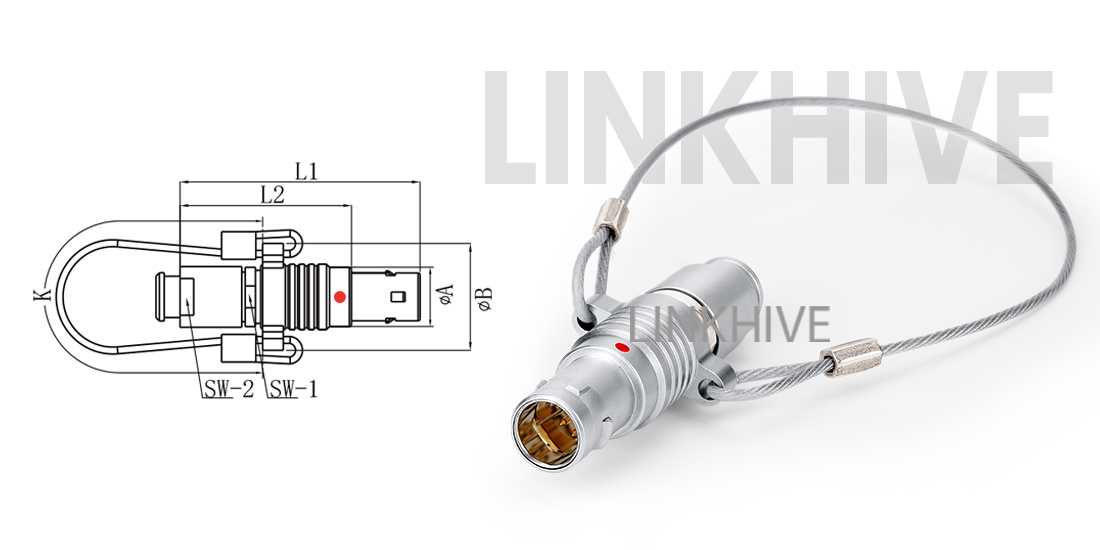

What is B Series FNG Lanyard Release circular push pull connectors?

The FNG 0B/1B to 4B 304 Lanyard Release circular push pull connectors are specially designed quick disconnect connectors that provide a secure connection with rapid-release capability. seal tight connector Equipped with a built-in lanyard mechanism, this circular push pull connector with lanyard allows users to quickly and safely disengage the connection by pulling the attached cord — ideal for mission-critical or hazardous applications.

As a avionics connector, the FNG connector with lanyard release meets the same performance standards, ensuring seamless integration into existing systems. The circular push pull connector with lanyard is manufactured with precision-machined metal shells, available in sizes 0B through 4B, and offers various pin configurations suitable for both signal and power transmission.

Typical Applications:

The FNG lanyard-release connector is used in situations where fast, tool-free disconnection is essential:

Military field equipment and tactical gear

Aerospace and drone control modules

quick disconnect connectors for medical or monitoring devices

Test & measurement setups requiring hot-swap capability

Harsh-environment data transmission with quick disengagement

Key Advantages

Quick Disconnect Connectors with Quick-release lanyard pull — ideal for emergency disconnection or one-handed operation

Push-pull self-latching mechanism with secure lock before release

Rugged metal housing with chrome plating, designed for repetitive field use

Available with multiple keying codes and contact arrangements (signal, power, hybrid)

Customizable lanyard length and pull force

Electrical Configuration

Fast disconnection avionics connector Contact Termination: Solder

Maximum Contact Resistance (R): 4.8 mΩ

seal tight connector Insert Configuration: Low Voltage

Insulator Material: PEEK / PPS

Rated Current: 10 A

Test Voltage (DC): 1.6 kV

Wire Size Compatibility: AWG 30 – 22

Contact Range: 2 to 47 contacts

Material & Environmental Performance

Part No Description: FNG avionics connector with key (G or A–L), cable collet, nut for bend relief.

Gender: Quick Disconnect Connectors

Plug Material: Chrome-plated brass shell and back nut; nickel-plated brass latch sleeve and internal components

Locking Mechanism: Circular push-pull connector

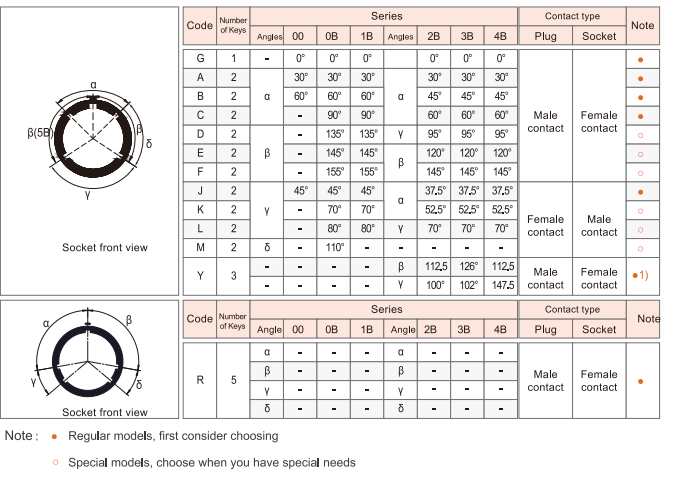

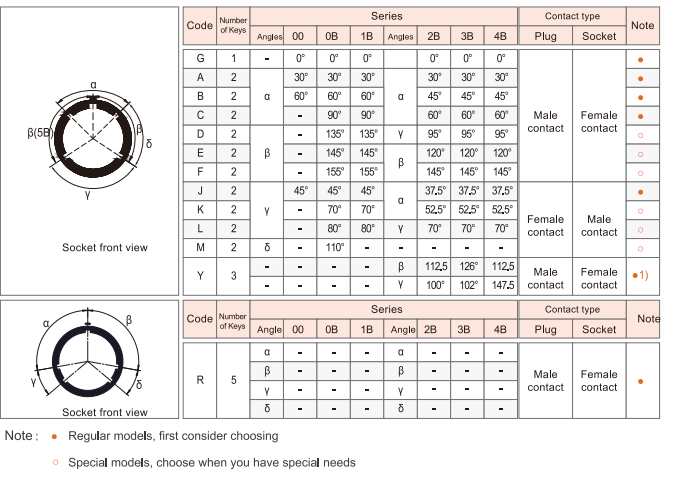

Keying Options: Key G / A / B / C / D / E / F / J / K / L / M / V / R

Contact Count: 2 to 47

Endurance: 5000 mating cycles

Temperature Range: -55°C to +250°C

Shielding at 10 MHz: >75 dB

Shielding at 1 GHz: >40 dB

Shock Resistance: 100 g / 6 ms

Vibration Resistance: 15g (10 Hz – 2000 Hz)

Climatic Category: 50/175/21

Humidity Resistance: ≤95% at 60°C (140°F)

Mating/Unmating Cycles: 5000

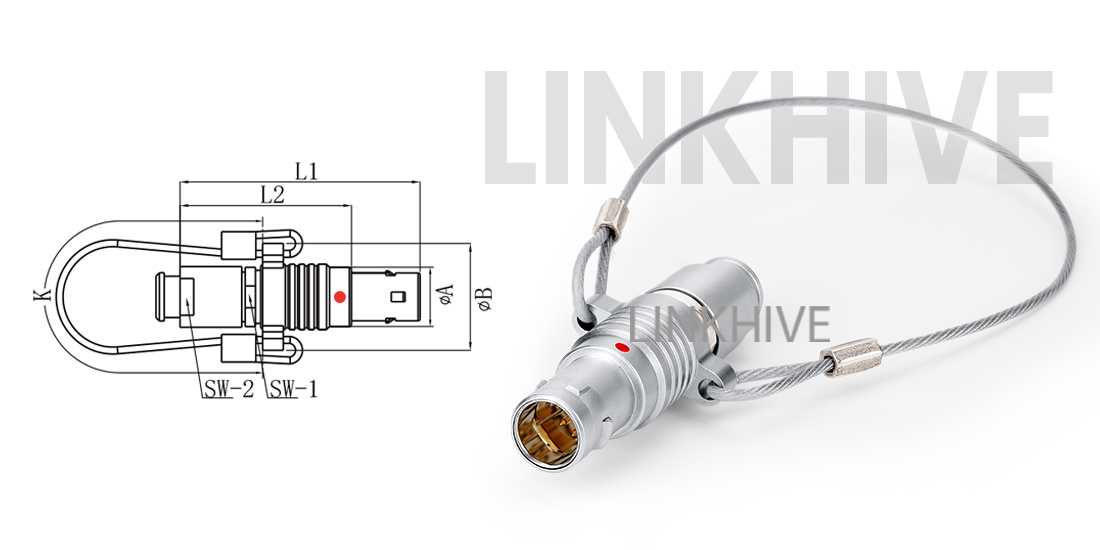

FGN connector with lanyard release

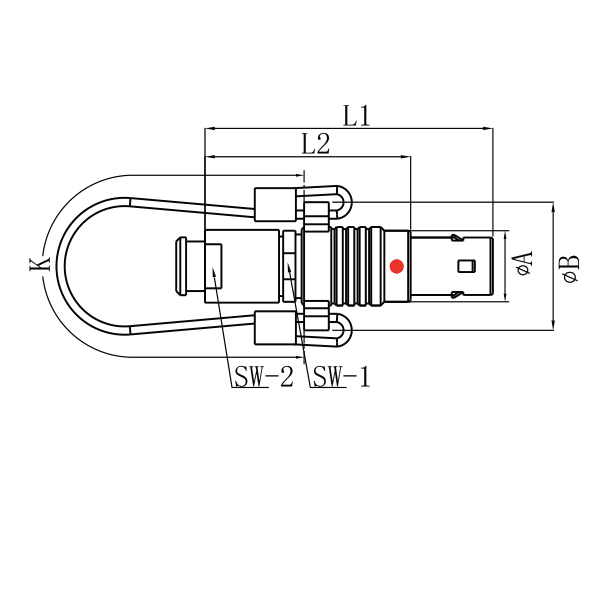

Model & Dimension Overview

| Reference | FGN connector with lanyard release Dimensions (mm) |

| Series | Model | A | B | L1 | L2 | K | SW1 | SW2 |

| 0B | TNG | 9.5 | 15.5 | 35 | 25 | 140 | 8 | 7 |

| 1B | TNG | 12 | 18 | 42 | 31 | 140 | 10 | 9 |

| 2B | TNG | 15 | 21 | 49 | 37 | 160 | 13 | 13 |

3B

| TNG | 18 | 25 | 58 | 43 | 190 | 16 | 15 |

| 4B | TNG | 25 | 35.2 | 74 | 56 | 230 | 21 | 20 |

Quality & Testing

To ensure safe and repeatable disconnection in critical scenarios, the FNG quick disconnect connectors series undergoes the following quality checks:

Mating/unmating endurance: ≥5000 cycles without locking failure for Quick Disconnect Connectors

Lanyard pull force validation: Each unit tested to release at calibrated force

seal tight connector Vibration testing: 15g @ 10–2000Hz

Shock testing: 100g / 6ms impact validation

Salt spray resistance: 96 hours (plating and housing corrosion test)

Insulation & contact resistance: Verified to meet electrical performance

Assembly integrity: Each batch includes visual inspection, torque test on lanyard crimp, and lock confirmation

Quick Disconnect Connectors B Series Alignment key

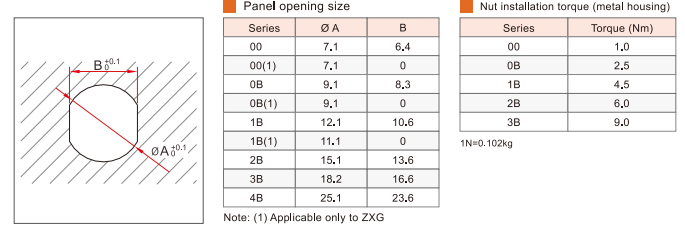

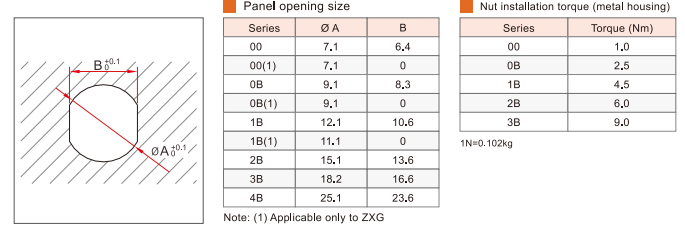

Quick Disconnect Connectors B Series Panel cutouts

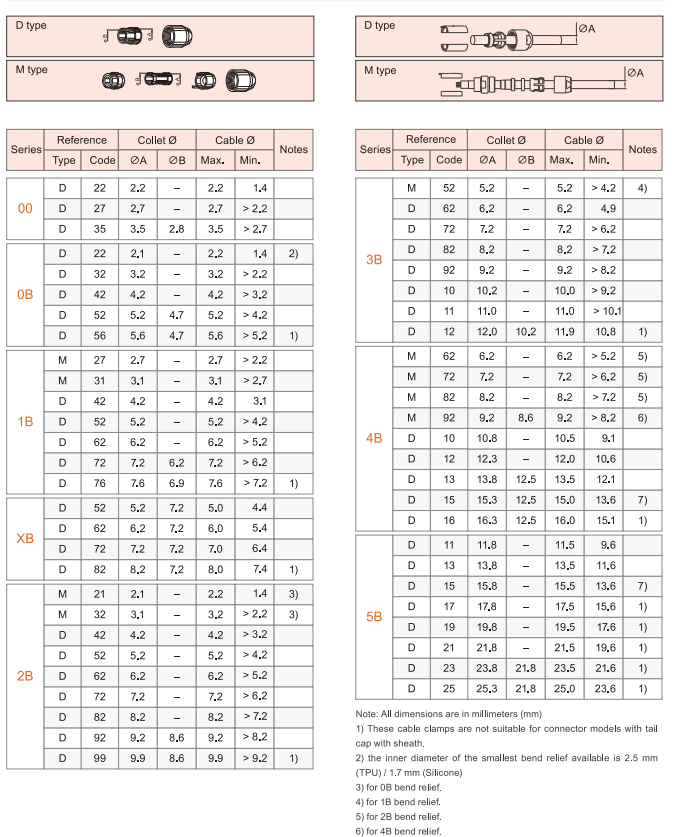

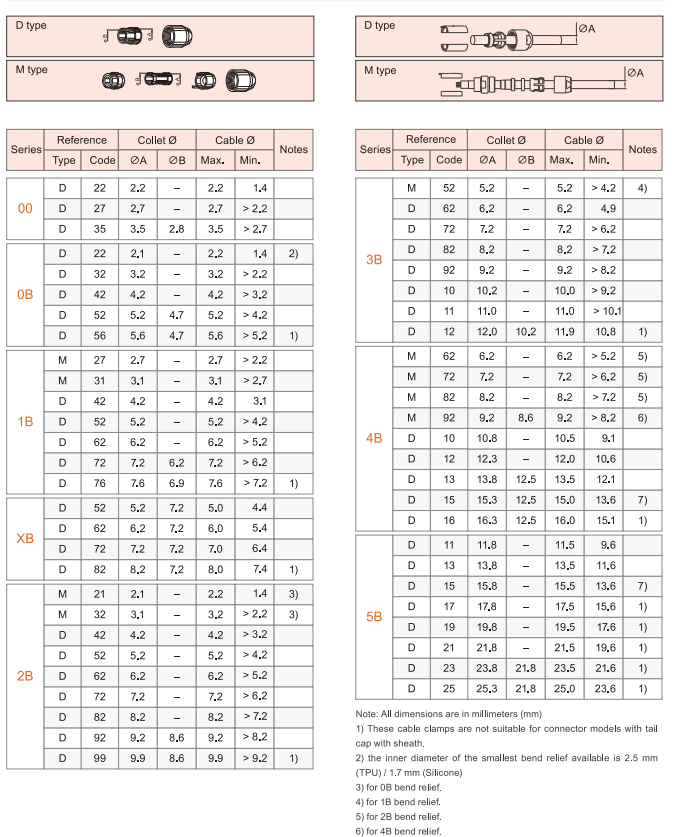

Seal Tight Connector B Series Clamp