As a convenient and reliable electrical connection method, push pull connectors are widely used in various fields. Whether in the military, industry, aerospace, or in industries such as medical equipment and communication equipment, push pull connectors have been increasingly widely used due to their easy operation, high stability and reliable connection performance.

As the frequency of use of push pull electrical connectors in practical applications continues to increase, many people have begun to think about a question: "Can old push pull connectors be reused?" This article will explore this issue in depth, analyzing whether push pull connectors can continue to maintain their performance after multiple uses, and how to ensure reliability during repeated use.

What are push pull connectors?

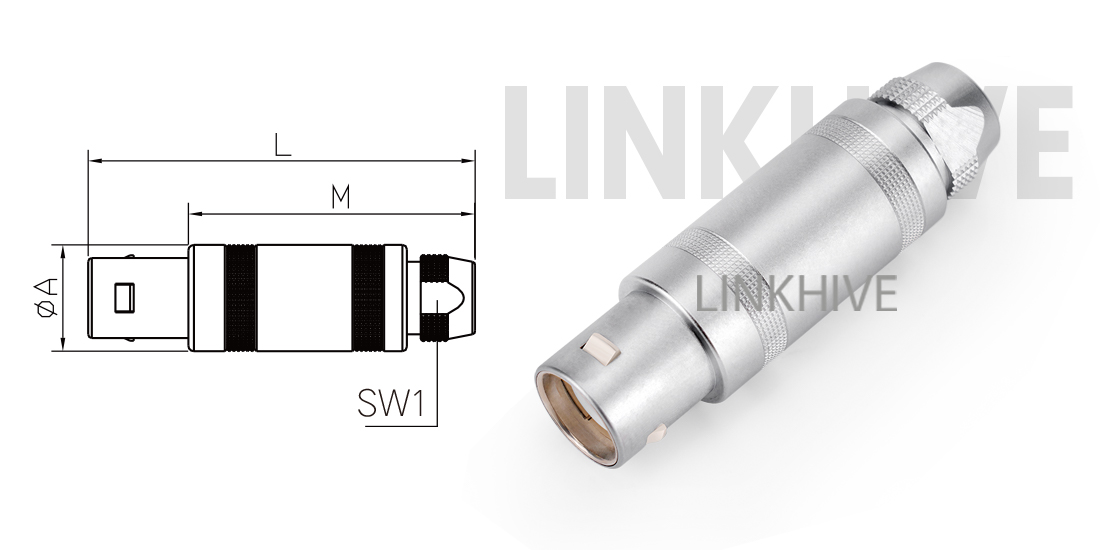

Push pull connectors are an electrical connector with a unique plug-in and pull-out method. Its main feature is that it is connected and disconnected by pushing and pulling operations. Unlike traditional rotary or snap-on connectors, push pull electrical connectors are simple and quick to plug and unplug, and do not require complex tools or additional rotation operations. Push pull connectors usually include a plug and a socket. During the connection process of the plug and the socket, the locking mechanism inside the connector is automatically enabled to ensure that the connection is stable and not easy to loosen.

The design of push pull electrical connectors takes into account a variety of environmental factors, such as waterproof, dustproof, vibration-resistant, and high temperature resistant, to meet the use requirements in various harsh environments. Therefore, it is widely used in industries that require high reliability, such as military, aerospace, communications, and medical.

Reuse of push pull connectors

Before discussing whether old push pull electrical connectors can be reused, we first need to understand the working principle, material, and mechanical and electrical performance of push pull connectors when they are designed. The reusability of push pull connectors is directly related to their long-term stability and reliability.

1. Working principle of push pull connectors

Push pull connectors connect and disconnect through a simple push-pull action. When connecting, the plug is inserted into the socket by pushing until the internal locking mechanism automatically locks, ensuring a firm connection between the plug and the socket. When disconnecting, pull the plug to release the locking mechanism and safely separate the connector.

The internal contact points of push pull electrical connectors are made of high-quality metal materials, which have good conductivity and can withstand a certain number of plug-in and pull-out operations. However, during repeated plugging and unplugging, metal contact points may be worn, especially in the case of high-frequency plugging and unplugging or improper operation, which may lead to increased contact resistance, unstable connection and other problems.

2. Design considerations for push pull connectors

The design purpose of push pull electrical connectors is to ensure that the connector can maintain stable electrical and mechanical properties during multiple use cycles. Therefore, push pull connectors are usually designed with high-strength materials such as stainless steel, aluminum alloy or titanium alloy to ensure high wear resistance and corrosion resistance. At the same time, the plugging and unplugging mechanism of push pull connectors is also precisely designed to ensure that it can withstand multiple plugging and unplugging operations.

However, although the design of push pull electrical connectors takes into account the needs of multiple uses, actual use may affect its service life. For example, environmental factors such as high temperature, humidity, corrosive gases, etc. will affect the performance of push pull connectors. Especially in some harsh environments, push pull connectors may experience poor contact, failure or other failures after a period of use.

3. Material and durability of push pull connectors

The durability of push pull electrical connectors is closely related to its material. Push pull connectors are usually made of materials with high mechanical strength and corrosion resistance, which allows them to work stably in environments such as high temperature, humidity, and vibration. However, as the number of uses increases, the contact points, housing, and locking mechanism of the connector will gradually wear out. Especially in the case of frequent plugging and unplugging, strong plugging and unplugging, or harsh environments, the external and internal structures of push pull electrical connectors may be damaged, thus affecting the performance of the connector.

For example, if the contact points of the plug and the socket are repeatedly plugged and unplugged, they may produce slight wear due to friction, which will increase the contact resistance and may even cause poor electrical contact. If the metal contact points used in push pull connectors are oxidized or corroded, the performance of the connector may also be degraded.

What is the service life of push pull connectors?

The service life of push pull connectors is usually determined by their mechanical life and electrical life. Mechanical life refers to the number of plugging and unplugging times that the contact and locking mechanism between the plug and the socket can withstand during the plugging and unplugging process of the connector. Electrical life refers to the time that the contact points of the connector can maintain a stable electrical connection during long-term use.

Mechanical life

The mechanical life of push pull electrical connectors is usually between a few thousand and tens of thousands of times. High-quality push pull connectors, especially those made of wear-resistant materials, have a longer mechanical life and can withstand more plugging and unplugging operations. But even for high-quality push pull electrical connectors, after long-term and high-frequency use, the connector's locking mechanism, the contact points between the plug and the socket and other components will be worn, resulting in increased plugging and unplugging resistance, reduced connection firmness, and ultimately affecting performance.

Electrical life

The electrical life of push pull electrical connectors is mainly related to the quality and material of the contact points and the working environment of the connector. If the contact points of the connector are affected by factors such as frequent plugging and unplugging, corrosion, and oxidation, it may cause poor electrical contact or even complete failure. High-quality push pull electrical connectors usually use materials such as gold or silver plating to prevent oxidation and corrosion of the contact points, but over time, these protective layers may wear due to excessive plugging and unplugging, which in turn affects the electrical performance of the connector.

Can old push pull connectors be reused?

From a technical point of view, whether push pull connectors can be reused depends on their material, design, working environment and number of times used. Here are some factors to consider:

1. Limitation of plugging and unplugging times

Push pull connectors are usually designed to withstand a certain number of plugging and unplugging operations. For most industrial-grade push pull connectors, their design life is generally more than 5,000 times. For some high-end push pull electrical connectors, the number of plugging and unplugging can reach 10,000 times or more. With reasonable use, push pull electrical connectors should be able to work stably before reaching the design life. However, frequently exceeding the recommended number of plugging and unplugging times or using them in harsh environments will accelerate the aging and wear of the connectors.

2. Influence of the external environment

The use environment of push pull connectors has an important impact on their life. Factors such as high temperature, humidity, and chemical corrosion will accelerate the aging process of push pull connectors and affect their mechanical and electrical properties. If push pull electrical connectors are exposed to harsh environments for a long time, it may cause corrosion and oxidation of metal contact points, and even cause aging of plastic or rubber parts. To ensure that push pull electrical connectors can be reused, excessive environmental stress should be avoided as much as possible during use, and regular inspections should be performed.

3. Regular inspection and maintenance

In order to extend the service life of push pull electrical connectors and ensure their reliability in repeated use, regular inspection and maintenance are essential. Checking whether the connector's exterior is damaged, whether the contact points are oxidized or worn, and whether the locking mechanism is working properly are the key to ensuring that the connector continues to work reliably. If any abnormality is found, timely replacement or repair can effectively avoid safety hazards caused by connector failure.

4. Technological innovation and material upgrade

With the development of technology, more and more push pull electrical connectors use more durable materials and more sophisticated designs. For example, push pull electrical connectors using new alloys or corrosion-resistant materials can withstand higher frequencies of use and harsher environmental conditions, thereby extending their service life. Therefore, choosing the right push pull connectors and performing regular maintenance according to usage are the keys to ensuring their reliable use.

The answer to the question "Can old push pull connectors be reused?" depends on many factors, including the design quality, materials, working environment, and number of plugging and unplugging of the connector. In general, push pull connectors are designed with repeated use in mind, and many high-quality push pull electrical connectors can be plugged in and out multiple times while ensuring their service life.