Connectors are essential components in modern electronic devices, communication systems, industrial automation, and other technical fields. With the advancement of technology, the types and designs of connectors are also evolving to meet more complex and diverse needs. Push Pull Connectors are a type of connector that has gradually gained attention in recent years. With its unique design and advantages, Push Pull Connectors have been widely used in many fields.

This article will explore the advantages of push pull electrical connectors and analyze their performance in practical applications.

What are Push Pull Connectors?

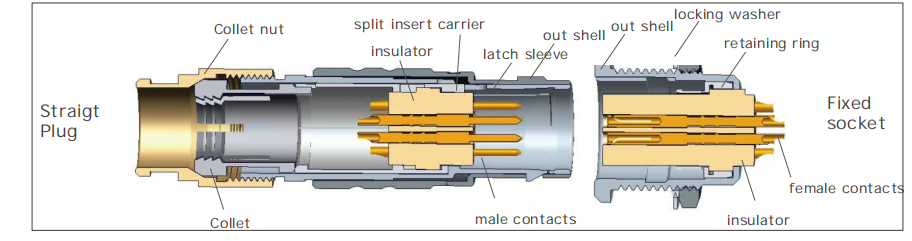

Push Pull Connectors are connectors that connect or disconnect electrical contacts by push-pull actions. The design of this connector makes the plugging and unplugging process easier and has higher mechanical stability. When operating, the user only needs to push one end of the connector into the socket until the connection is in place; when disconnecting, just pull the other end. Compared with traditional rotating or snap-on connectors, Push Pull Connectors are more intuitive and convenient to operate, especially for occasions that require frequent plugging and unplugging.

The design of Push Pull Connectors not only focuses on convenience, but also takes into account electrical performance, mechanical stability, and environmental adaptability. Therefore, Push Pull Connectors are widely used in multiple industries, including communications, medical, automation, military, aerospace and other fields. Its unique advantages enable it to perform well in environments that require high reliability and stability.

What are the advantages of Push Pull Connectors?

The design and structure of Push Pull Connectors give them many unique advantages, especially in terms of performance, ease of operation and application environment. The following are some of the main advantages of Push Pull Connectors.

Easy operation and time saving

One of the biggest advantages of push pull electrical connectors is its simple operation method. Traditional connectors may require complex operations such as rotation or snapping to achieve plugging and unplugging, while Push Pull Connectors only need to push and pull to complete the connection and disconnection. This operation method not only reduces the time required to plug and unplug connectors, but also reduces the possibility of operating errors, greatly improving work efficiency.

In some occasions where devices need to be frequently connected and disconnected (such as on-site equipment maintenance or equipment upgrades), Push Pull Connectors can especially save time and facilitate users to complete operations quickly and efficiently. Moreover, since the plugging and unplugging process of Push Pull Connectors does not involve complex mechanical movements, users can complete the operation in a simple and intuitive way, reducing the complexity of use.

High reliability and stability

The design of push pull connectors emphasizes reliability and stability. Its contacts and mechanical structures are usually made of high-strength and durable materials such as stainless steel and copper alloy, which not only provide strong structural support, but also have corrosion resistance and wear resistance. Especially in harsh environments, push pull electrical connectors can still maintain their connection quality and stability, ensuring smooth transmission of electrical signals.

In addition, the contacts of push pull connectors are generally made of high-precision manufacturing technology to ensure the stability and durability of the contact. Its spring-type or plug-in contact design can ensure stable contact when the connector is plugged in and out, preventing poor contact. This design enables push pull electrical connectors to work stably for a long time under high-frequency use, high vibration or harsh environments.

Prevent mis-insertion

Push pull electrical connectors usually have a unique plug-in and pull-out method, so that they can only be operated in the correct direction when inserted, thereby preventing mis-insertion. This design is crucial in many application scenarios, especially in equipment that requires high safety and electrical stability. Misinsertion may cause electrical failure, equipment damage or system crash, and the design of Push Pull Connectors reduces this risk.

In addition, push pull electrical connectors are usually equipped with an anti-reverse connection design, which ensures that the contacts are correctly inserted even if a little too much force is applied during connection, avoiding electrical failure caused by wrong insertion direction.

Excellent mechanical protection

Push Pull Connectors not only excel in electrical performance, but also in mechanical protection. Since the insertion of connectors is generally completed by push-pull action, they have strong resistance to vibration, tension and compression. In harsh working environments, push pull electrical connectors can ensure that the connection parts are not damaged by external physical forces.

The shell of Push Pull Connectors is usually made of metal or high-strength plastic materials, which have excellent performance in high temperature resistance, corrosion resistance and chemical resistance. Therefore, in high temperature, high humidity, high pressure or corrosive environment, Push Pull Connectors can still maintain stable operation and ensure long-term reliable operation of equipment.

Waterproof and dustproof function

Many Push Pull Connectors are waterproof and dustproof, which can effectively block the intrusion of external pollutants such as moisture, dust, and sand. By sealing the outside of the connector, push pull electrical connectors can achieve a higher IP protection level (such as IP67, IP68), and even in wet, muddy or dusty environments, push pull electrical connectors can still provide stable electrical connections.

This waterproof and dustproof feature makes push pull electrical connectors have important application value in environments such as offshore platforms, outdoor equipment, military applications, and communication base stations. Being able to withstand the challenges of harsh environments and ensure long-term stable operation of equipment is a major advantage of Push Pull Connectors.

Diverse application areas

Push Pull Connectors perform well in a variety of applications, especially in situations where high reliability and easy operation are required. For example, in medical equipment, Push Pull Connectors can ensure that the equipment maintains the stability of electrical connections during frequent plugging and unplugging; in aerospace and military equipment, Push Pull Connectors can withstand high vibration and extreme environmental conditions to ensure that the equipment always works properly; in the field of industrial automation, push pull electrical connectors can provide efficient signal transmission and mechanical protection.

This diverse adaptability makes Push Pull Connectors widely used in power, automobile, medical, communication, aerospace and other fields, and has become an indispensable and important part of many high-demand equipment.

High-quality electrical performance

Push Pull Connectors not only have advantages in mechanical aspects, but also have excellent electrical performance. The design of Push Pull Connectors ensures low contact resistance and stable current transmission, and is suitable for various voltage and current applications. By optimizing the material and contact force of the contact parts, push pull electrical connectors can provide high-quality electrical connections, reduce signal loss, and ensure signal integrity and stability.

In some high-frequency and high-speed signal transmission applications, push pull electrical connectors can also maintain the quality of signal transmission, prevent interference, signal loss or delay, and thus ensure the overall performance of the system.

What are the applicable scenarios of Push Pull Connectors?

Push Pull Connectors have been widely used in many industries and fields due to their unique advantages. The following are several common application scenarios of Push Pull Connectors:

● Communication equipment: push pull electrical connectors are often used in network equipment, broadcasting and television, wireless communication and data transmission equipment. Due to their high reliability and simple operation, they are widely used in field installation and maintenance.

● Medical equipment: In medical equipment, push pull electrical connectors are widely used in medical diagnosis, monitoring, detection and treatment equipment. Due to their waterproof and dustproof characteristics, they are very suitable for high-precision medical environments.

● Military and aerospace: Push Pull Connectors can meet the needs of extreme environments, such as high temperature, high humidity, strong vibration, etc., so they are widely used in military equipment and aerospace equipment to ensure the high reliability of the equipment.

● Industrial automation: push pull electrical connectors can provide stable electrical connections in industrial automation equipment to prevent equipment failures due to connection problems, and are key components in automation systems.

● Automobile: Push Pull Connectors are widely used in automotive electronic equipment, automotive lighting systems, electric vehicle charging systems, etc. to ensure the stable operation of electrical systems.

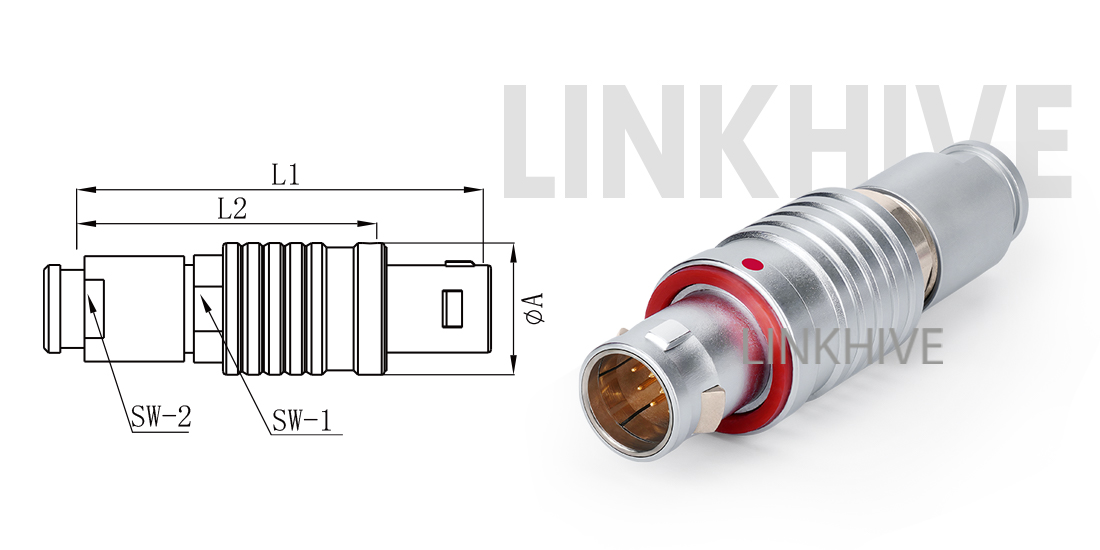

With a focus on precision and innovation, LINKHIVE has been at the forefront of connector manufacturing since 2010. We offer an extensive array of over 2,000 standard connectors, including push-pull, M series circular, and coaxial connectors. Our customizable options cater to industries like aerospace, automotive, medical, and telecommunications, ensuring durability and performance. As a trusted supplier, we offer competitive prices, affordable bulk buying options, and customized solutions to meet your unique needs.