As a widely used connector in the industrial and automation fields, the M12 connector has become an indispensable part of many industrial systems due to its compactness, ruggedness and high protection. The M12 connector provides reliable electrical connections between various devices and plays a vital role in many fields such as modern industrial automation, robotics, sensor networks, etc. To ensure the reliability and stability of the M12 connector, it is crucial to understand its rating.

This article will focus on the topic of "What is the rating of the M12 connector?" and comprehensively interpret the technical parameters of the M12 connector, such as rated voltage, rated current, rated power, etc., as well as the impact and importance of these ratings in different application scenarios.

What is an M12 connector?

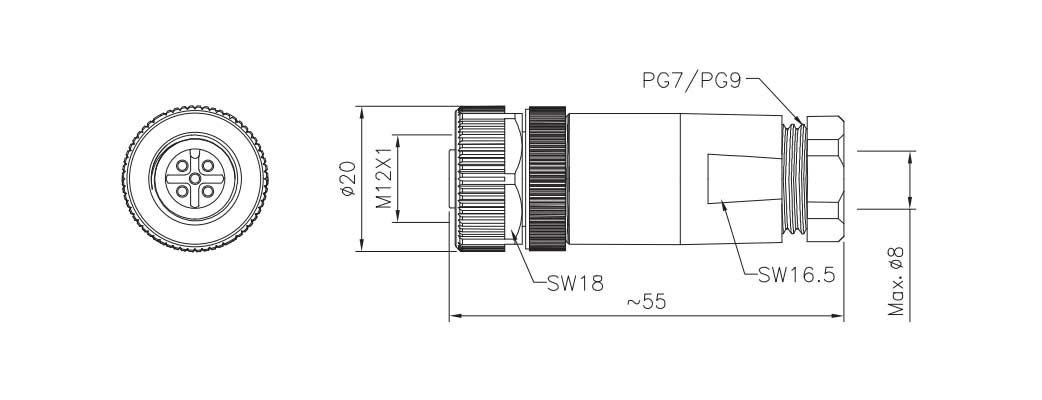

The M12 connector is a common industrial connector with a standard 12 mm outer diameter, usually in a circular design, and available in a variety of models and configurations. The shell of the M12 connector is usually made of metal or engineering plastics, with built-in high-quality contact elements, and has extremely high anti-interference ability and durability. They are often used to connect sensors, actuators, controllers, and other industrial automation equipment.

Common interface types of M12 connectors include power interface, signal interface, data interface, etc., which are widely used in industrial automation, communication, automobile, robotics and other fields. In these applications, the rated values of M12 connectors (such as current, voltage, power, etc.) directly affect the performance and reliability of the equipment. Therefore, understanding the rated values of M12 connectors is the basis for selecting and applying M12 connectors.

What is the rated voltage of M12 connectors?

The rated voltage of M12 connectors refers to the maximum operating voltage at which the connector can operate safely and stably. For most M12 connectors, there are usually several common standards for rated voltage: 24V, 48V and 250V. However, the specific rated voltage varies according to different application scenarios and design specifications of the connector.

1. Low voltage application (24V)

In industrial automation and sensor networks, 24V is the most common rated voltage. Many industrial devices, sensors and actuators operate at 24V because this voltage is moderate and sufficient to meet the power supply needs of the equipment. For these applications, the rated voltage of the M12 connector is usually 24V. This allows the M12 connector to maintain a stable working state when transmitting power and signals between devices, avoiding damage or failure of the equipment due to unstable voltage.

2. Medium voltage application (48V)

In some industrial occasions, especially in some high-power equipment, the rated voltage of 48V is widely used. The M12 connector can also work normally at this voltage. In some communication equipment and transmission control systems, the rated voltage of 48V can provide enough power to meet the power demand of the equipment without generating too much heat, thus ensuring the efficient operation of the equipment.

3. High voltage application (250V)

For some special-purpose M12 connectors, such as those used for high-power equipment or systems requiring long-distance power transmission, the rated voltage can reach 250V. In these high-voltage applications, the rated voltage of the M12 connector must ensure that it can still maintain a safe and stable working state under high voltage. This type of M12 connector is usually equipped with higher-specification insulation materials and has stronger resistance to electric shock and leakage.

Understanding the rated voltage of the M12 connector is crucial to choosing the right connector. Too high or too low voltage can cause equipment failure or connector damage, so you need to make sure that the rated voltage of the M12 connector matches the application scenario.

What is the rated current of the M12 connector?

The rated current of the M12 connector refers to the maximum current value that the connector can continuously and safely transmit under specified working conditions. The rated current depends on the design of the M12 connector, the material of the contact elements, and the structure of the connector. Depending on the model and application requirements, the rated current of the M12 connector is usually between 1A and 12A.

1. Low current application (1A-5A)

In sensors, signal interfaces, and low-power devices, the rated current of the M12 connector is usually between 1A and 5A. For example, in many sensors or low-power automation equipment, M12 connectors are often used for signal transmission. These signals do not require a lot of current support, so the rated current of the connector is relatively low.

2. Medium current applications (5A-8A)

Some more complex automation equipment and robot control systems require higher current transmission. In this case, the rated current of the M12 connector is usually 5A to 8A. These applications involve motors, actuators and other power drive devices, and the current demand is relatively large, so the design of the M12 connector needs to take into account higher current carrying capacity.

3. High current applications (8A-12A)

In high-power industrial equipment or drive systems, the rated current of the M12 connector may reach 12A. Such applications require higher current support, such as in the power supply system of some large mechanical equipment or high-power communication systems. The high rated current of the M12 connector ensures that the equipment can work stably and will not cause overheating or damage to the contact elements due to excessive current.

The rated current is a key parameter in the design of the M12 connector. Excessive current may cause the contact point to burn, poor contact or even connector failure, while too low a rated current will limit the normal operation of the equipment. Therefore, when selecting an M12 connector, it is necessary to ensure that its rated current meets the actual needs of the equipment.

What is the power rating of an M12 connector?

The power rating of an M12 connector refers to the maximum power that the connector can carry when it is operating normally. The power rating is usually calculated as the product of voltage and current, that is, P = U × I, where P is power, U is voltage, and I is current. Depending on the rated voltage and current, the power rating of an M12 connector can vary greatly.

For example, if the rated voltage of an M12 connector is 24V and the rated current is 5A, its rated power is 120W; if the rated voltage is 48V and the rated current is 8A, its rated power is 384W. In some high-power applications, the M12 connector needs to support higher power transmission to meet the power requirements of the device.

The power rating also plays an important role in the selection of M12 connectors. Too much power can cause the connector to overheat or fail, while too little power cannot meet the needs of the device. Therefore, when applying an M12 connector, it is critical to understand its power rating and ensure that it matches the needs of the system.

Rated temperature and durability of M12 connectors

In addition to voltage, current and power, the rated temperature and durability of M12 connectors are also important parameters. The working environment of M12 connectors may include a variety of extreme conditions such as high temperature, high humidity, vibration, etc., so the rated operating temperature and durability of the connector are also important considerations in the design.

1. Rated operating temperature: The rated operating temperature range of M12 connectors is usually -40°C to +85°C, but some models can withstand a wider temperature range according to different application requirements. The selection of insulation materials and contact elements of M12 connectors takes into account the adaptability to high and low temperature environments to ensure that the connector can work stably in harsh environments.

2. Durability: The durability of M12 connectors is usually measured by the number of plug-in and unplug operations. Most standard M12 connectors are designed to withstand 500 to 1000 plug-in and unplug operations, while high-quality connectors can even reach a plug-in life of more than 5000 times. This high durability makes M12 connectors widely used in industrial automation and robotics, meeting the needs of long-term high-frequency plugging and unplugging.

Since its establishment in 2010, LINKHIVE has become a prominent supplier of precision connectors, offering over 2,000 standard solutions and customized designs tailored to meet the demands of various industries. From military-grade connectors to high-quality molded cable assemblies, our products are designed for durability and superior performance. We provide wholesale pricing and bulk discounts to help businesses reduce costs while maintaining quality. Whether you're looking to purchase connectors in bulk or need a custom solution, LINKHIVE offers competitive quotes, fast delivery, and world-class customer service.