Electrical connectors play a vital role as key components for power and signal transmission. Among them, M12 and M16 connectors are two common models that are widely used. They differ in appearance, size, installation method, performance characteristics, etc., but each has its own unique advantages and application areas.

Although M12 connectors and M16 connectors are similar in some aspects, they have significant differences in design and performance requirements. Understanding the difference between the two will help engineers and designers make the right decisions when choosing the right connector. This article will discuss in detail the definition, characteristics, structure, application areas and main differences between M12 connectors and M16 connectors.

What is M12 connector?

M12 connector is a common circular industrial connector that is widely used in industrial automation, sensors, control systems and other places that require reliable electrical connections. The name of M12 connector comes from its external thread size-a diameter of 12 mm. M12 connectors are usually used for the connection of small and medium-sized equipment, with a high level of protection and reliability, and are particularly suitable for environments that require waterproofing, dustproofing and vibration resistance.

The main features of the M12 connector include its small size, easy installation, and high sealing. The M12 connector is widely used in industrial automation, sensor networks, robotics, transportation and other fields. Due to its compact design and high durability, the M12 connector provides an efficient, stable and safe solution for electrical connections in these industries.

What is the M16 connector?

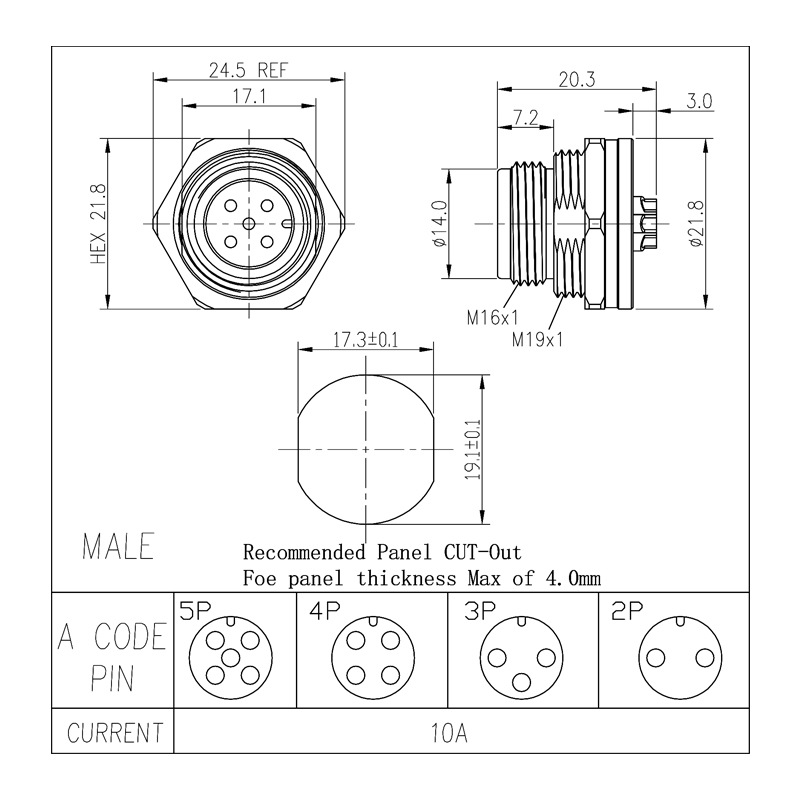

The M16 connector is similar to the M12 connector and is also a circular connector. The external thread size of the M16 connector is 16 mm, which is suitable for larger and higher power devices. Due to its relatively large size, the M16 connector is usually used in application scenarios that require higher current or greater mechanical strength. The M16 connector is widely used in industrial control, automotive electronics, energy, military applications and other fields.

The design of the M16 connector usually focuses on high current and high power transmission, and has good protection performance, which can adapt to more complex and harsh working environments. The M16 connector provides a very reliable connection solution in industrial equipment, machine connections and complex electrical systems.

Structure and design of M12 and M16 connectors

Size and shape

The outer diameter of the M12 connector is 12 mm, while the outer diameter of the M16 connector is 16 mm, so the M16 connector has a larger size than the M12 connector. The M16 connector usually has a larger contact point and stronger mechanical strength, which is suitable for devices that require higher power and higher current, while the M12 connector is more suitable for applications with limited space due to its compact design.

Contacts and current transmission capacity

M12 connectors are generally designed for low-power or medium-power applications, and the current transmitted is usually between 2A and 12A. Common configurations include 3, 4, 5, and 8 pins. Due to its smaller contact surface and lower current transmission capacity, M12 connectors are usually used for smaller sensors, automation equipment, etc. M16 connectors are usually used for higher current transmission, and the current transmission capacity is generally between 10A and 20A, so they are suitable for applications that require higher currents, such as motor control, power systems, etc.

Installation and wiring methods

Both M12 and M16 connectors use threaded installation to ensure stability during connection and prevent loosening. They are usually designed to be plug-in, which is convenient for quick installation and removal. M12 connectors usually have fewer pins, while M16 connectors have relatively more pins, which adapt to more complex electrical connection requirements.

Protection level and sealing

Both M12 and M16 connectors have a high protection level, usually IP67 or higher, which means that they can prevent the intrusion of dust and liquids and adapt to use in harsh environments. Whether under complex conditions such as high temperature, high humidity, chemical corrosion, vibration, etc., both connectors can ensure stable electrical performance. Especially in some extreme application environments, such as automotive electronics, outdoor equipment, etc., M16 connectors can often provide higher strength protection due to their larger size and higher load-bearing capacity.

Application areas of M12 and M16 connectors

M12 connectors and M16 connectors are widely used in many fields, but due to differences in their size, current transmission capacity and design characteristics, they have different advantages in some specific application scenarios.

Industrial Automation

In the field of industrial automation, M12 connectors are widely used for connecting sensors, actuators, industrial robots and other equipment due to their compact design and small size. M12 connectors are suitable for occasions that require small space and have high requirements for waterproofing and dustproofing. In contrast, M16 connectors are suitable for equipment with higher power, such as motor control, large electrical systems in automation equipment, etc., especially in some high-current applications, the larger size and higher power transmission capacity of M16 connectors make it an ideal choice.

Transportation and Automotive Electronics

In the automotive and transportation industries, M12 connectors are often used to connect on-board electronics, sensors, intelligent systems and other equipment. Its compactness and high protection make it well adaptable in the on-board environment. M16 connectors play an important role in automotive power systems, battery management systems and other high-current transmission applications. M16 connectors can provide higher current carrying capacity and adapt to the needs of automotive electrical systems for high-power transmission.

Energy and Power

In the energy field, M16 connectors are often used to connect large electrical equipment such as wind power generation, solar panels, and transmission systems. Due to its high current carrying capacity and mechanical strength, the M16 connector is suitable for high-voltage and high-power electrical connections. The M12 connector is widely used in some low-power electrical systems, such as sensors, monitoring equipment, etc., to ensure the stable operation of the equipment.

Medical equipment

The medical industry has extremely high requirements for the safety and reliability of electrical connections. Due to its small size and high protection level, the M12 connector is usually used for the connection of medical instruments, life support systems and other equipment. Due to its higher power transmission capacity, the M16 connector is usually used in some high-power medical equipment, such as MRI, X-ray machines, etc.

Military and aerospace

In the military and aerospace fields, M16 connectors are often used in complex electrical systems and can withstand harsh environments such as high temperature, vibration, and moisture to ensure the normal operation of the equipment. M12 connectors are also widely used in some low-power devices, especially in military communications and sensor systems.

What are the main differences between M12 and M16 connectors?

Although M12 and M16 connectors have certain similarities in appearance, they have significant differences in many aspects, especially in electrical performance, structural design, application scenarios, etc.

The following are the main differences between M12 and M16 connectors:

Dimensional differences

Current carrying capacity

Contact points and number of pins

Application environment and working conditions

1. Dimensional differences: The outer diameter of the M12 connector is 12 mm, while the outer diameter of the M16 connector is 16 mm. The M16 connector is larger than the M12 connector and is suitable for devices that carry higher power and current.

2. Current carrying capacity: The M12 connector is suitable for low-power or medium-power applications, and the current carrying capacity is usually between 2A and 12A. The M16 connector is suitable for high-power applications, and the current carrying capacity is generally between 10A and 20A, which is suitable for motor control, high-power equipment and other occasions.

3. Contact points and number of pins: The M12 connector usually has a small number of pins and is suitable for simple electrical connections. The M16 connector has a relatively large number of pins and is suitable for complex electrical systems, which can meet more signal transmission requirements.

4. Application environment and working conditions: Due to its small size and high protection performance, the M12 connector is suitable for environments with limited space and high sealing and waterproof and dustproof requirements. The M16 connector is suitable for environments with higher current and voltage requirements, such as high-power equipment and large industrial control systems.

LINKHIVE is a leader in connector manufacturing, with more than 2,000 standard products and a wide array of custom-designed solutions. We offer connectors for a variety of applications, including medical, aerospace, automotive, and telecommunications. As a trusted manufacturer, we ensure that all our products meet international certifications, including UL, RoHS, and ISO9001. We pride ourselves on providing durable connectors at low prices. Buy wholesale or purchase customized solutions at affordable rates and enjoy competitive quotes from LINKHIVE. Our connectors are built for performance, ensuring reliability in every industry.