In modern industrial and automation technology, connectors play a vital role as key components in electrical and mechanical systems. Whether in factory automation, data transmission, or various industrial equipment, connectors play a decisive role in maintaining system reliability and stability. As a common industrial connector, the M12 connector has been widely used in many industries.

This article will delve into the topic of "What is the M12 connector used for", and analyze in detail the definition, characteristics, application areas of the M12 connector, and its important role in modern industry.

What is the M12 connector?

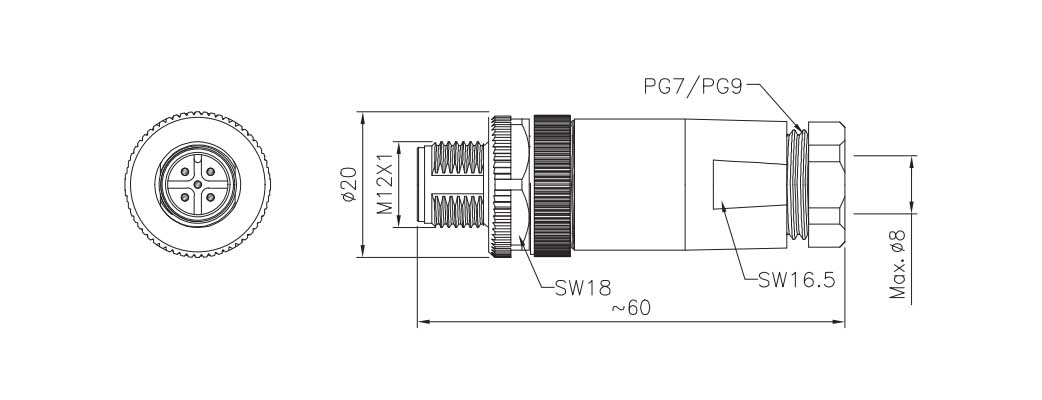

The M12 connector refers to a circular electrical connector with an outer diameter of 12 mm. The "M12" in its name represents its thread size. As a standardized connector, the M12 connector is widely used in many fields such as industrial automation, sensor connection, data transmission, and communication equipment. The design of the M12 connector is usually a circular plug and socket structure, and it has a thread locking mechanism to ensure a firm and reliable connection.

The M12 connector is mainly used in high-demand environments, especially those application scenarios with high requirements for connection stability, anti-interference, dust and water resistance. Compared with other types of connectors, M12 connectors have strong anti-interference ability, vibration resistance and protection, which makes it perform well in complex environments.

What are the structural characteristics of M12 connectors?

The design structure of M12 connectors mainly includes the following important parts:

1. Shell and contact elements

2. Thread locking mechanism

3. Sealing and protective devices

4. Terminal blocks

1. Shell and contact elements

The shell of M12 connectors is usually made of metal or engineering plastics, which can effectively protect the internal contact points from the intrusion of the external environment. The contact element is the core part of the connector, responsible for transmitting current, signals or data. In order to ensure long-term stable electrical performance, the contact element is usually made of highly conductive materials such as copper alloys, and gold or silver is plated on its surface to reduce contact resistance.

2. Thread locking mechanism

The M12 connector adopts a thread locking mechanism to firmly connect the plug and the socket by tightening it. This design can effectively avoid loose or unstable connections, especially in environments with vibration and impact, the thread locking mechanism can ensure the safety and stability of the connector.

3. Sealing and protection devices

M12 connectors are usually equipped with sealing devices, such as O-rings, gaskets, etc., to ensure the waterproof and dustproof performance of the connector. These sealing devices can prevent moisture, dust, oil, etc. from entering the connector, thereby avoiding the degradation of electrical performance. The protection level of M12 connectors usually meets IP67 or higher standards and is suitable for various complex working environments.

4. Terminal blocks

The terminal blocks of M12 connectors are usually designed with plug-in or screw type, which is convenient and quick to wire. The design of the terminal blocks enables M12 connectors to be connected to different types of cables, sensors or devices, with high versatility.

What are the application areas of M12 connectors?

Due to its unique performance characteristics, M12 connectors have been widely used in many industries.

The following are some common application areas of M12 connectors:

1. Industrial automation

2. Robotics

3. Automotive industry

4. Communications industry

5. Medical equipment

6. Food and beverage industry

1. Industrial automation

Industrial automation is one of the most important application areas of M12 connectors. With the continuous development of automation technology, the number of equipment used in factory production processes is increasing, and the demand for connectors is also growing. In automated production lines, M12 connectors are mainly used to connect various sensors, actuators, control systems, and data transmission systems. M12 connectors can ensure the stability and reliability of transmission, and have characteristics such as waterproof, dustproof, and oil-proof, making them suitable for use in various harsh environments.

Equipment in industrial automation usually has problems such as vibration, temperature changes, and high humidity. The anti-interference, vibration resistance, waterproof and dustproof characteristics of M12 connectors make them an ideal choice in this field. They are widely used to connect sensors, photoelectric switches, temperature sensors, pressure sensors and other equipment.

2. Robotics

In robotics, M12 connectors also have important applications. With the widespread use of industrial robots on production lines, reliable connections between robot control systems and sensors and actuators have become increasingly important. With its sturdy structure and protective design, M12 connectors can withstand the complex operating environment of robots, such as high temperature, high humidity, vibration, and shock.

The role of M12 connectors in robot control systems is mainly to provide stable signal transmission, power supply, and connection with peripheral equipment to ensure that robots can work efficiently and stably. In addition, since M12 connectors usually adopt standardized designs, they are compatible with a variety of robot systems and their components, which facilitates modular design and maintenance.

3. Automotive industry

M12 connectors are also widely used in the automotive industry. With the development of automotive electronic technology, more and more parts involving electrical connections are involved in automobiles. Sensors, actuators, control systems and other equipment require reliable and stable electrical connections, which makes M12 connectors play an important role in automotive electronics.

In the electrical system of the car, M12 connectors are used to connect engine control units, transmission system control modules, sensors, on-board communication equipment, etc. The high reliability, waterproof and dustproof, anti-vibration and anti-interference characteristics of M12 connectors enable it to meet the needs of various harsh working environments in the automotive industry, such as high temperature, humidity, vibration, etc.

4. Communications industry

M12 connectors are also widely used in the communications industry. With the development of data transmission and communication technology, the performance requirements of communication equipment for connectors are also increasing. As a connector with excellent electrical and mechanical properties, M12 connectors are often used for signal and data transmission connections between various communication equipment.

In communication base stations, switches, routers and other equipment, M12 connectors are used to connect components such as sensors, antennas, and monitoring equipment. Due to the high protection level and stability of the M12 connector, it can ensure data transmission in harsh environments and effectively avoid connection failures caused by environmental factors (such as moisture, dust, etc.).

5. Medical equipment

The requirements for connectors in the field of medical equipment are also very high, especially in areas involving precision instruments, medical sensors, and patient monitoring systems. M12 connectors have been widely used in medical equipment due to their compactness, ruggedness, and high reliability.

In medical equipment, M12 connectors are mainly used to connect sensors, monitoring equipment, diagnostic equipment, etc. Its waterproof, dustproof, and anti-interference properties make it suitable for use in medical environments, especially for some equipment that needs to work in humid, clean, and disinfected environments. M12 connectors can ensure stable and fast electrical connections between medical devices, thereby improving the working efficiency and accuracy of the equipment.

6. Food and beverage industry

Automation equipment in the food and beverage industry has high requirements for connectors. M12 connectors have become an ideal connector choice in this industry due to their waterproof, dustproof, and corrosion-resistant properties. In automated production lines, bottling and packaging equipment, M12 connectors are used to connect various sensors, actuators and control systems.

Due to the high requirements for hygiene, cleanliness and corrosion protection in the food and beverage industry, M12 connectors can effectively meet these requirements and ensure stable operation of production equipment in high humidity, high pressure and strong cleaning requirements.

What are the advantages of M12 connectors?

M12 connectors perform well in a variety of application fields, mainly due to their various advantages.

Here are several main advantages of M12 connectors:

1. Strong protection

2. High reliability

3. Stable connection

4. Easy to install and maintain

5. Strong durability

1. Strong protection

M12 connectors are usually designed to meet IP67 or higher protection levels, which can effectively prevent water, dust and other pollutants from entering the connector, ensuring the reliability and stability of the connector in harsh environments. This allows it to be widely used in complex working environments such as humid, dirty, high temperature and strong vibration.

2. High reliability

The M12 connector uses a threaded locking mechanism to ensure that the plug and socket are firmly connected, avoiding looseness or poor contact caused by vibration, impact and other factors. Its stability and anti-interference enable it to provide high-reliability connections in industrial automation, communications, automotive and other fields.

3. Stable connection

The M12 connector adopts a standardized design and is compatible with a variety of devices. Whether in data transmission, signal processing or power supply, the M12 connector can provide stable and reliable electrical connections to ensure the normal operation of the system.

4. Easy to install and maintain

The M12 connector usually adopts a threaded locking structure, which makes the connection and disconnection operations simple and convenient. Due to its standardized design, the maintenance and replacement of the M12 connector is also relatively easy, reducing system downtime and maintenance costs.

5. Strong durability

The structural design of the M12 connector is sturdy and durable, and can withstand large mechanical loads and environmental pressures. This allows it to maintain good performance during long-term use, reduce the frequency of replacement, and extend its service life.

LINKHIVE, based in Dongguan, China, is a premier manufacturer of precision connectors, offering an extensive selection of over 2,000 standard products. We specialize in providing custom connector solutions for industries such as aerospace, telecommunications, medical, and automotive. Our commitment to high-quality manufacturing and cost-effective pricing sets us apart from the competition. We offer low prices, bulk purchasing discounts, and competitive quotes to ensure you get the best value for your investment. Whether you're looking for a specific connector or bulk supply, LINKHIVE is your trusted supplier for reliable, affordable solutions.