The M12 connector is a common and widely used connector, especially in industrial automation, sensors, robots, control systems and other fields. The name of the M12 connector comes from its outer diameter size, that is, the outer diameter of the connector is 12 mm. The popularity of the M12 connector is not only due to its rugged design and reliable performance, but also because it can adapt to a variety of different application scenarios and provide a variety of specifications, interfaces and electrical characteristics.

In this article, we will focus on an important aspect related to the M12 connector - the code of the M12 connector. The code of the M12 connector is not just a simple identifier, it represents a series of electrical and mechanical characteristics of the connector. Understanding these codes is essential for choosing the right connector.

The code system of the M12 connector

The code of the M12 connector is a multi-part identifier that is used to describe the various characteristics of the connector, including its type, purpose, pin configuration, connection method, etc. Usually, the code of the M12 connector consists of a series of letters and numbers, each part represents a different characteristic of the connector.

1. Connector size and type (e.g. M12)

The "M12" code of the M12 connector is a direct identification of the outer diameter of the connector. M12 means that the outer diameter of the connector is 12 mm, which is also its most basic identification. M12 connectors are usually used to connect electrical transmission between cables and devices, especially for occasions with high space requirements.

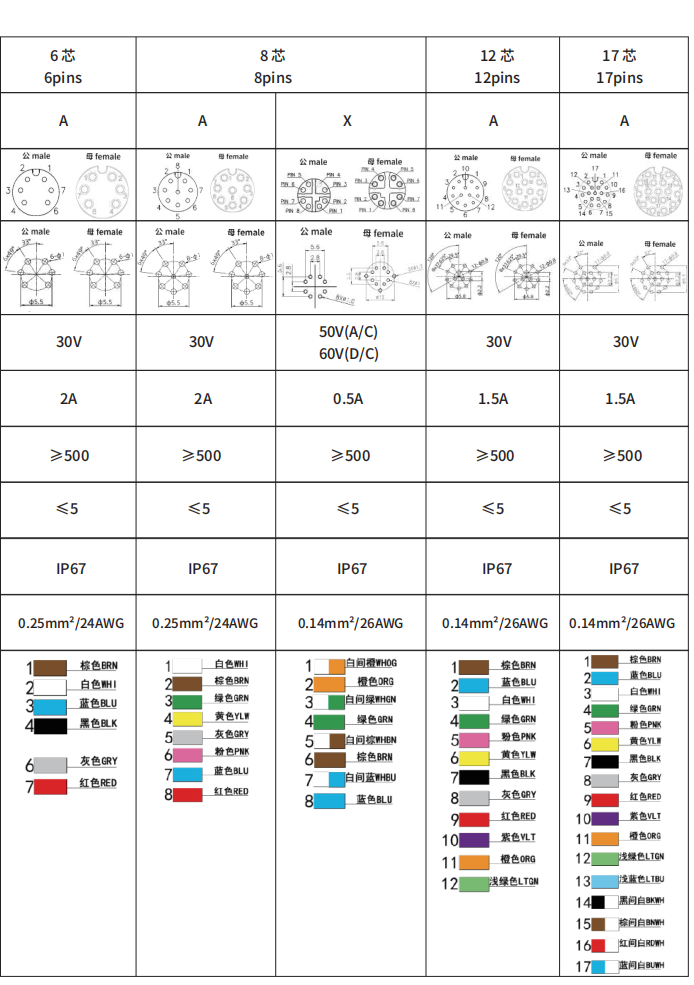

2. Pin configuration (e.g. 3P, 4P, 5P, etc.)

The code of the M12 connector also includes a number, usually ranging from 2 to 12, which represents the number of pins of the connector. Different application scenarios may require different numbers of signal or power transmission channels, so choosing the right pin configuration is crucial to the performance of the device.

● 3P (3-pin): represents a connector with 3 pins, usually used in low-power applications.

● 4P (4-pin): represents a connector with 4 pins, commonly used in industrial sensor connections.

● 5P (5-pin): represents a connector with 5 pins, used in occasions requiring multi-channel signal transmission.

3. Connection method (e.g. A-type, B-type, etc.)

The M12 connector code also includes letters indicating the connection method, which indicate different designs and locking methods of the connector. The most common connection methods are:

● A-coding: used for common industrial signal transmission, usually used for sensors and automation equipment.

● B-coding: usually used for Ethernet connection, with different pinouts and designs.

● D-coding: specially used for high-speed data transmission, often used in industrial networks and control systems.

4. Protection level (e.g. IP67, IP68, etc.)

The M12 connector code usually also includes the protection level identification. The protection level is usually composed of "IP" followed by a number, which represents the connector's ability to be waterproof and dustproof.

● IP67: indicates that the connector has the ability to be dustproof and short-term submerged in water, suitable for use in most industrial environments.

● IP68: indicates that the connector has the ability to be completely dustproof and long-term submerged in water, suitable for more demanding environments, such as outdoor or underwater equipment.

5. Material and voltage rating (e.g. metal or plastic)

The code of the M12 connector may also include descriptions of the material and voltage rating, which are critical to the performance and adaptability of the connector. Common materials include:

● Metal housing: has higher durability and is suitable for environments that require high mechanical strength.

● Plastic housing: is light in weight and suitable for occasions with light weight requirements.

The voltage rating is usually closely related to electrical performance. Common markings include 250V, 500V, etc., indicating the highest voltage that the connector can withstand.

Different application fields and code interpretation of M12 connectors

M12 connectors are widely used in industrial automation, traffic control, medical equipment, communication systems and other fields due to their excellent design and performance. Depending on different application requirements, the codes of M12 connectors will also be different. The following are several common application scenarios and code interpretations.

1. Industrial automation

In the field of industrial automation, M12 connectors are usually used to connect sensors, actuators, PLCs (programmable logic controllers) and other devices. Its code may include A-coding and 4-pin or 5-pin configuration to meet the transmission requirements of different signals and power supplies. The protection level is generally IP67, ensuring that the connector can effectively prevent dust and moisture from entering in the factory environment.

Example: M12 A-coding 4P, protection level IP67.

2. Ethernet applications

With the rise of the industrial Internet, M12 connectors are increasingly used in Ethernet devices. At this time, the code of the M12 connector will include B-coding, and usually supports high-speed data transmission. M12 Ethernet connectors generally have IP67 or IP68 protection levels to adapt to harsh industrial environments.

Example: M12 B-coding 4P, supports 1000 Mbps rate, protection level IP67.

3. Medical equipment

In medical equipment, M12 connectors are often used for high-precision instruments and medical monitoring equipment. Since medical equipment has strict requirements for electrical safety and protection, the code of M12 connectors usually includes D-coding for high-speed data transmission, and the protection level is usually IP67 or higher.

Example: M12 D-coding 5P, protection level IP68.

4. Traffic control and vehicle-mounted equipment

M12 connectors are also very common in traffic control and vehicle-mounted equipment. These devices usually need to operate for a long time in a vibration and humid environment, so the code of M12 connectors will include metal shells and higher protection levels, such as IP67 or IP68.

Example: M12 metal shell, 4P connector, protection level IP68.

How to choose M12 connectors correctly?

Choosing a suitable M12 connector should not only be based on its code, but also be considered comprehensively according to the actual application scenario. The following are several key points to pay attention to when choosing an M12 connector:

1. Determine the number of pins: When choosing an M12 connector, first confirm how many signal or power channels the connector needs to carry. Normally, the common pin numbers in industrial equipment are 3P, 4P, and 5P, which are selected according to electrical requirements.

2. Choose the correct coding method: The coding of the M12 connector determines its applicable functions and transmission types. Choose different coding methods such as type A (signal transmission), type B (Ethernet), and type D (high-speed data transmission) according to actual needs.

3. Consider the protection level: For equipment used in harsh environments, it is necessary to choose an M12 connector with a higher protection level, such as IP67 or IP68, to ensure that it can resist the intrusion of moisture, dust, and other pollutants.

4. Applicable materials and voltage resistance levels: Choose appropriate materials and voltage resistance levels according to the use environment and working conditions of the equipment. For example, when used in a high-pressure environment, it is necessary to choose an M12 connector with a higher voltage resistance level; for environments that require high temperature resistance and corrosion resistance, a connector with a metal shell and corrosion-resistant materials should be selected.

Since 2010, LINKHIVE has been a leading name in connector manufacturing, delivering precision connectors for various industries, including aerospace, telecommunications, and medical devices. Our catalog features over 2,000 standard items, with customized solutions available to meet your unique requirements. With certifications like UL and RoHS, our products guarantee top-notch quality and durability. As a leading supplier, we offer affordable pricing, wholesale options, and excellent customer service. Contact LINKHIVE for your connector needs and get the best connector on prices high-quality connectors designed for exceptional performance.