In modern industry, electronics, medical, military and communications, the performance of connectors directly determines the stability and reliability of equipment. Among them, Push Pull Connectors are widely used in many industries due to their advantages such as fast plug-in and pull-out, self-locking structure, high density and strong anti-interference ability.

So, what are Push Pull Connectors used for? This article will discuss the application scenarios of Push Pull Connectors in detail and analyze their importance in different fields.

What are Push Pull Connectors?

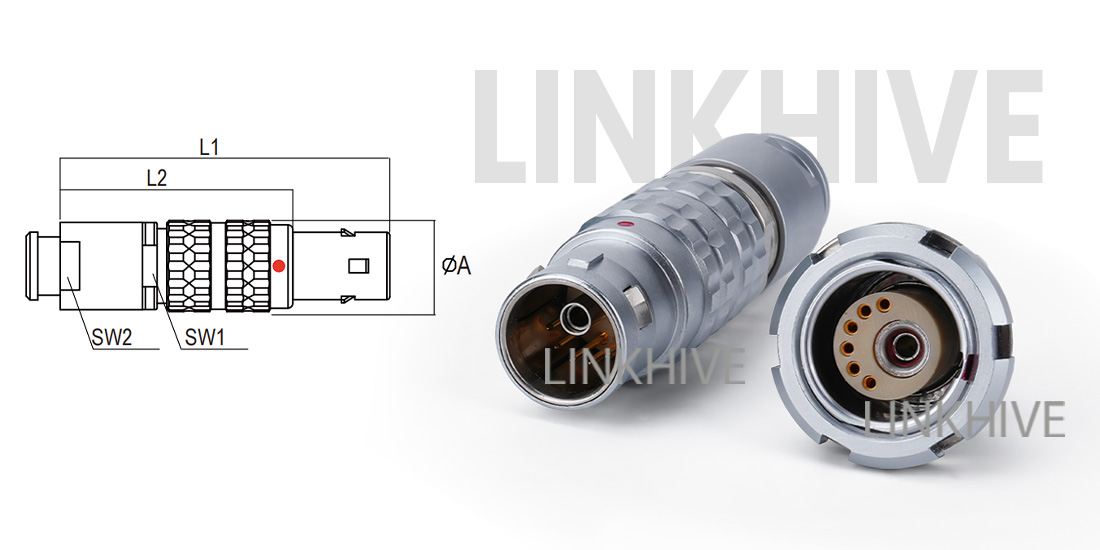

Push Pull Connectors are an electrical connector with a self-locking mechanism, mainly composed of a plug (male) and a socket (female). When the plug is inserted into the socket, the internal spring locking mechanism will automatically lock to ensure a stable connection. When disconnection is required, just gently pull the shell to quickly unlock. This design greatly improves the convenience of connection and disconnection.

Push pull electrical connectors usually use high-strength metal shells and high-performance contacts, which can provide reliable electrical connections in extreme environments, so they are widely used in equipment and systems with extremely high stability requirements.

What are Push Pull Connectors used for?

Medical equipment

Push Pull Connectors are widely used in the field of medical equipment, especially for key equipment such as operating room equipment, monitors, and diagnostic instruments. The medical industry's requirements for push pull electrical connectors include fast plugging and unplugging, anti-pollution, high temperature disinfection resistance, waterproof and dustproof, etc. Push pull electrical connectors fully meet these requirements with their excellent performance.

● Medical imaging equipment (such as CT, MRI, and ultrasound equipment): ensure high-quality signal transmission and avoid image distortion.

Patient monitoring equipment (such as electrocardiographs and blood pressure monitors): ensure long-term stable connection and avoid data loss.

● Surgical instruments (such as electric scalpels and endoscopes): support frequent plugging and unplugging to ensure smooth operation.

In addition, Push Pull Connectors are usually made of medical-grade plastic or stainless steel, which can withstand the erosion of cleaning fluids such as disinfectants and alcohol, and meet strict medical equipment standards.

Industrial Automation

Push Pull Connectors play a key role in application scenarios such as intelligent manufacturing, industrial control, and robots. Since industrial environments are usually accompanied by adverse factors such as high temperature, dust, vibration, and electromagnetic interference, ordinary connectors are difficult to operate stably for a long time, while Push Pull Connectors can ensure the efficient operation of equipment.

● PLC control system: Push Pull Connectors are used to connect PLC modules to ensure stable signal transmission and improve the automation level of production lines.

● Robots and sensors: Push Pull Connectors are used in components such as robot end effectors, servo motors, and visual sensors to provide precise power and signal connections.

● Machine tools and CNC processing equipment: Vibration-resistant and oil-resistant push pull electrical connectors can operate stably in high-precision machine tools and CNC machining centers.

In addition, the IP67/68 protection level of Push Pull Connectors ensures that they are not affected in harsh industrial environments and provide highly reliable electrical connections.

Aerospace

The requirements for push pull electrical connectors in the aerospace field are extremely strict. Push pull electrical connectors are widely used in spacecraft, satellites, drones, flight control systems and other equipment due to their high reliability, vibration resistance, and extreme temperature resistance.

● Flight Data Recorder: Push Pull Connectors are used to connect devices such as black boxes to ensure data storage and transmission in extreme environments.

● Satellite Communication System: Used for connection between antennas and communication modules to ensure the stability of long-distance data transmission.

● Avionics System: Including flight instruments, autopilot systems, navigation equipment, etc., Push Pull Connectors provide high-precision signal connections.

Because aerospace equipment needs to operate in extreme environments such as high vacuum, high and low temperature cycles, and electromagnetic interference, Push Pull Connectors usually use gold-plated contacts and aviation-grade materials to ensure long-term stability and durability.

Military and Defense

Push pull electrical connectors are widely used in military equipment, including communication equipment, radar systems, weapon control systems, night vision devices, electronic warfare systems, etc. Military equipment requirements for push pull electrical connectors include high temperature resistance, impact resistance, waterproof and dustproof, electromagnetic shielding, etc., and push pull electrical connectors fully meet these requirements.

● Battlefield communication equipment: Such as military radios and satellite communication systems, Push Pull Connectors ensure the stability of signal transmission.

● UAV and missile systems: high-density Push Pull Connectors are used for precise control and navigation systems to ensure the normal operation of equipment.

● Military computers and surveillance equipment: used to connect data processing units, providing anti-interference and high-speed data transmission capabilities.

Military applications usually need to comply with MIL-SPEC standards (military specifications). The metal shielding shell of Push Pull Connectors can effectively reduce electromagnetic interference (EMI) to ensure stable operation of equipment in complex battlefield environments.

Broadcasting and audio and video equipment

In industries such as television stations, film production, audio equipment, and live broadcast systems, Push Pull Connectors are widely used in high-definition cameras, microphones, audio mixers, video transmission equipment, etc. due to their high bandwidth, low loss, and high reliability.

● Broadcast-level cameras: ensure lossless transmission of high-definition video signals to meet high-end production needs.

● Professional audio equipment: push pull electrical connectors are used for high-end speakers, microphones, etc. to provide high-fidelity audio transmission.

● Studio connection system: a large number of Push Pull Connectors are required for internal wiring of radio and television stations to ensure rapid deployment and stable connection of equipment.

In high-end audio and video applications, push pull electrical connectors usually use gold-plated contacts to reduce signal loss and improve transmission quality.

Rail transit and automotive electronics

In the fields of high-speed rail, subway, automotive electronics, intelligent transportation systems, etc., Push Pull Connectors are used in various key electronic devices, such as train control systems, on-board cameras, GPS navigation systems, vehicle sensors, etc.

● Rail transit signal system: Push Pull Connectors ensure the stability of automatic control and communication systems of high-speed rail, subway and other trains.

● Automotive electronic systems: Such as ADAS advanced driver assistance systems, on-board radars, etc., Push Pull Connectors provide high-density, high-speed data connections.

● Charging piles and new energy equipment: In electric vehicles and new energy equipment, push pull electrical connectors provide stable power and data interfaces.

The anti-vibration performance of Push Pull Connectors can ensure that they maintain a stable connection on high-speed vehicles without being disturbed by the external environment.

In summary, push pull electrical connectors have a wide range of applications in multiple fields, including medical equipment, industrial automation, aerospace, military defense, radio and television, rail transportation, and automotive electronics. The advantages of push pull electrical connectors such as fast plug-in and unplug, high reliability, strong anti-interference ability, and resistance to harsh environments make them an indispensable core component of modern electronic equipment.

At LINKHIVE, we specialize in providing reliable, high-quality connectors for industries across the globe. Our extensive product range includes over 2,000 standard connectors and customized solutions, including push pull electrical connectors, coaxial, and high-pressure connectors. As a trusted manufacturer, we ensure that each product meets international certifications like UL, CE, and ISO9001. Our commitment to innovation and affordable pricing makes us the preferred supplier for companies looking for durable connectors at low prices. If you're looking to buy in bulk or need a custom connector solution, LINKHIVE offers tailored services to meet your needs.