M8 connectors and M12 connectors are common industrial connectors and are widely used in various devices and systems. The two connectors have certain differences in appearance, application range and performance characteristics, especially in size and function.

The names of M8 connectors and M12 connectors come from their outer diameters: the outer diameter of the M8 connector is 8 mm, while the outer diameter of the M12 connector is 12 mm. On the surface, the M12 connector is larger than the M8 connector, but this difference is not only reflected in size.

This article will focus on the question "Is the M12 connector larger than the M8 connector?" and explore their differences in appearance, performance, application, etc.

Dimensional differences between M8 connectors and M12 connectors

1. Outer diameter comparison

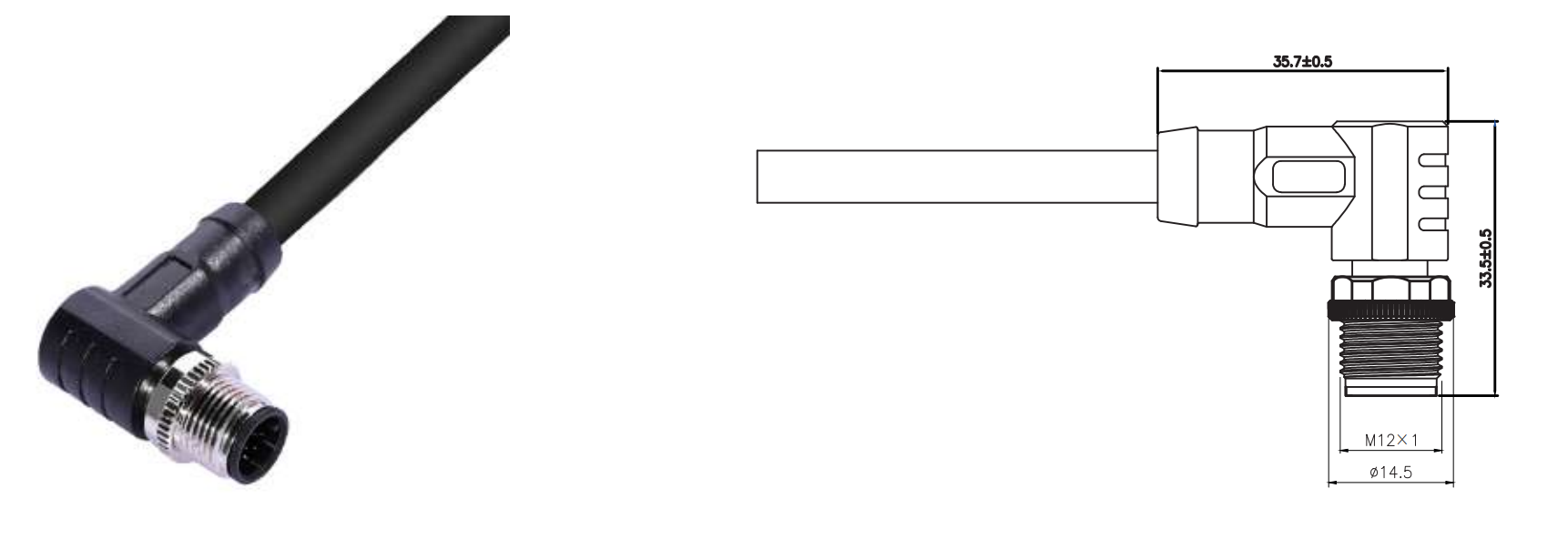

First of all, the most intuitive difference is the outer diameter of the two. The outer diameter of the M8 connector is 8 mm, while the outer diameter of the M12 connector is 12 mm. This size difference means that the M12 connector is larger and is usually used in applications that require higher current or larger physical size, while the M8 connector is usually used in space-constrained applications that require smaller size.

Regarding the issue of the M12 connector being larger than the M8 connector, the M12 connector is obviously larger in terms of outer diameter, and this increase in size directly affects the connector's appearance, internal structure, and application environment.

2. Connector volume and weight

Due to the larger outer diameter of the M12 connector, its overall volume and weight are generally higher than the M8 connector. M8 connectors are generally smaller and lighter, suitable for devices with limited space, while M12 connectors are generally more robust and can carry more electrical or data channels. Although their outer diameter difference is only 4 mm, in actual applications, this difference will have a certain impact on device design, installation space, and overall weight.

Structural differences between M8 and M12 connectors

1. Pin configuration

M8 connectors and M12 connectors usually have differences in pin configuration. M8 connectors usually offer a small number of pin options such as 3-pin, 4-pin or 5-pin, which are suitable for applications with low power or less signal transmission. In contrast, M12 connectors can provide a richer pin configuration, including 4-pin, 5-pin, 8-pin, 12-pin, etc., which are suitable for connection requirements that require higher current, more complex signal transmission or higher density. Therefore, the number of pins of M12 connectors is more, which is one of the reasons why it is larger and stronger than M8 connectors.

2. Material and protection design

The design of M8 connectors often focuses on compactness. Although its shell can be made of metal or plastic materials, the overall structure is lighter. M12 connectors usually use more robust materials and have a higher protection level. For example, the common protection level of M12 connectors is IP67 and IP68, which means that it has good dust and water resistance. The protection level of M8 connectors is relatively low, usually IP67. Therefore, in addition to its large size, the structural design of M12 connectors is usually more durable and suitable for use in more harsh environments.

Application fields of M8 connectors and M12 connectors

M8 connectors and M12 connectors also have significant differences in application fields. Although both are widely used in industrial automation, robots, sensors and other fields, their specific application scenarios are also different due to differences in their size, structure and electrical performance.

1. Application of M8 connectors

Due to the small size of M8 connectors, it is usually used in places with limited space and low signal transmission requirements. Common applications include:

● Sensor connection: Especially suitable for sensor device connection, such as temperature sensor, pressure sensor, etc.

● Automation equipment: M8 connectors are often used for robot control systems and signal transmission of automation equipment.

● Small equipment: Suitable for embedded systems and small control equipment, because of its compact size, it is easy to install in a small space.

2. Application of M12 connectors

Due to the large size of M12 connectors and higher current carrying capacity, it is usually suitable for equipment that requires higher voltage or more channels. Common applications include:

● Industrial automation and control systems: M12 connectors are often used in high-demand automation equipment and control systems.

● Ethernet connection: M12 connectors are widely used in industrial Ethernet, especially for data transmission and signal transmission.

● Power transmission: M12 connectors can carry larger currents, so they are often used in devices with large power connection requirements.

● Transportation industry: M12 connectors are also widely used in transportation systems, such as railway systems, vehicle detection systems, etc.

Differences in electrical performance between M8 connectors and M12 connectors

M8 connectors and M12 connectors are not only different in size and structure, but also have certain differences in their electrical performance, mainly reflected in current carrying capacity, voltage support capacity and signal transmission rate.

1. Current and voltage carrying capacity

Due to the larger size of the M12 connector, it can usually carry higher current and voltage. This makes the M12 connector more suitable for high-power applications and complex industrial systems. In contrast, due to its size limitations, the M8 connector is suitable for applications with lower current requirements.

● M8 connector: Generally suitable for occasions where the current does not exceed 4-5A, and the voltage is usually around 24V.

● M12 connector: It can carry more than 10A current and supports 250V voltage, so it is suitable for high-power and high-voltage industrial systems.

2. Signal transmission

M12 connectors usually support higher-speed signal transmission, especially in industrial Ethernet applications, where M12 connectors are widely used for high-bandwidth signal transmission. M8 connectors are more used for low-speed signals or simple digital/analog signal transmission.

Selection of M8 connectors and M12 connectors

When choosing a suitable connector, users need to decide whether to choose M8 connectors or M12 connectors based on specific application scenarios. The following factors are important considerations when choosing connectors:

1. Space requirements

If the device space is limited and a smaller connector needs to be selected, then the M8 connector is undoubtedly a more suitable choice. It is suitable for compact devices and small sensors.

2. Power requirements

If the application requires higher current and voltage carrying capacity, the M12 connector will be a better choice. It can meet the needs of high power transmission and complex industrial control.

3. Data transmission requirements

For applications that require high-speed data transmission, especially in industrial Ethernet, M12 connectors provide higher bandwidth and more stable transmission capabilities.

By comparing the size, structure, electrical performance and application areas of M8 and M12 connectors, it can be concluded that M12 connectors are larger than M8 connectors, not only in terms of the difference in outer diameter, but also in terms of their stronger electrical carrying capacity, more complex pin configuration and wider range of applications.

Although M8 connectors are suitable for some space-constrained applications due to their compact size, M12 connectors are undoubtedly a better choice in industrial environments that require higher current, more complex signal transmission or stronger protection.

LINKHIVE is your trusted partner for all your connector needs. With over 2,000 standard products and the capability to create customized connector solutions, we serve industries such as telecommunications, aerospace, medical, and automotive. Our products are engineered to meet the highest quality standards and are backed by global certifications like UL, CE, and RoHS. Whether you're buying in bulk or need a custom solution, we offer competitive pricing, low prices, and fast shipping. Trust LINKHIVE for reliable, high-performance connectors that meet your unique requirements.