Mil spec connectors are a type of high-performance connector designed for military, aerospace, defense and high-reliability industrial applications. Due to their outstanding performance in extreme environments, mil spec connectors are widely used in various mission-critical systems. How to correctly identify mil spec connectors is crucial to the reliability, safety and compatibility of equipment.

This article will focus on this topic and elaborate on the definition, standards, structural characteristics, identification methods and main technical indicators of mil spec wiring connectors to help readers correctly identify mil spec connectors.

What are mil spec connectors?

Mil spec connectors refer to electrical connectors that meet the standards of the US military or other international military industries. These connectors are usually developed and approved by the US Department of Defense (DoD) or other military agencies and meet strict mechanical, electrical and environmental performance requirements. Mil spec connectors are not only used in military systems such as radars, communication equipment, missile control, fighters, warships, etc., but are also widely used in aerospace, rail transportation, industrial automation, medical equipment and other fields with extremely high reliability requirements.

What are the standards for mil spec connectors?

The "Mil-Spec" in mil spec connectors is short for "Military Specification", which refers to the standards set by the U.S. Department of Defense and other related military agencies. All connectors that meet these standards can work normally under specific environmental conditions. The standard content of mil-spec wiring connectors covers the size, performance, material, life, durability, pressure resistance, protection level and other aspects of the connector.

Common mil-spec wiring connector standards include but are not limited to:

● MIL-PRF-39029: This is one of the standards for mil-spec wiring connectors, covering the electrical and mechanical characteristics of connectors.

● MIL-DTL-5015: This standard involves circular connectors and is widely used in military and aerospace fields.

● MIL-DTL-26482: This is another widely used standard that involves the size, form and performance requirements of connectors, especially in military and industrial applications.

● MIL-C-38999: This standard is used for aerospace connectors, which emphasizes the reliability and high temperature resistance of connectors.

These standards usually specify the electrical properties (such as contact resistance, insulation resistance, dielectric strength, etc.), mechanical properties (such as number of connections, insertion and extraction force, etc.), environmental adaptability (such as temperature range, humidity tolerance, etc.), and protection level of mil spec wiring connectors.

What are the characteristics of mil spec connectors?

Compared with ordinary industrial connectors, mil spec connectors have the following significant characteristics:

● High reliability: The design of mil spec connectors ensures high stability in extreme environments, and can maintain normal operation even in severe vibration, impact, high humidity, high temperature, low temperature or salt spray environments.

● Strong anti-environmental interference ability: mil spec connectors usually have shielding properties, which can effectively resist electromagnetic interference (EMI) and radio frequency interference (RFI) to ensure signal integrity.

● Corrosion resistance: Most mil spec connectors use special plating, such as nickel, gold or other anti-corrosion materials to prevent oxidation and chemical corrosion.

● Rugged and durable: mil spec connectors are usually made of aluminum alloy or stainless steel, with stronger mechanical strength and can withstand extreme physical stress.

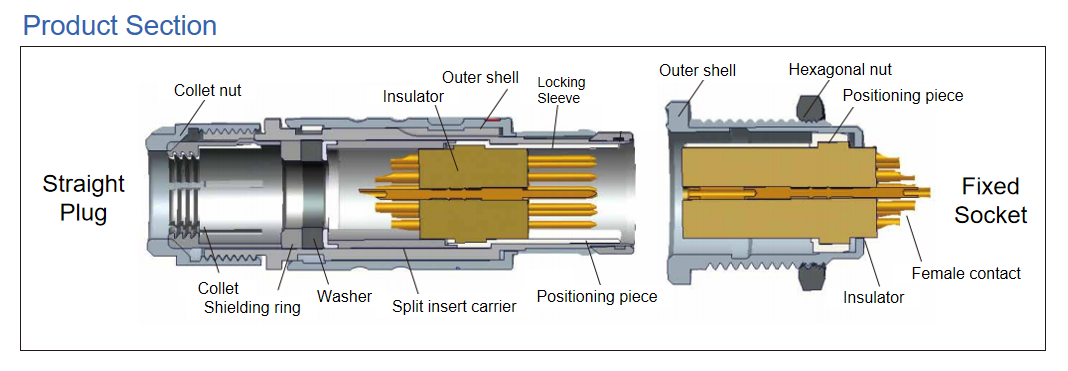

● Modular design: The pins and sockets of mil spec wiring connectors can be customized according to needs, supporting the transmission of various currents, voltages and signal types.

● High sealing: Most mil spec connectors have a protection level of IP67 or higher, which can prevent impurities such as moisture and dust from entering the connector.

What are the common types of mil spec connectors?

Mil spec connectors have many different types depending on the application scenarios and needs. The following are several common types of mil spec wiring connectors:

1. Circular Connectors

Circular connectors are the most common type of mil spec wiring connectors. They are commonly used in aviation, aerospace, warships and ground force equipment, and are widely used in power transmission and signal transmission. Circular mil spec wiring connectors generally have high protection levels, waterproof and dustproof characteristics, and can operate stably in harsh environments.

2. Rectangular Connectors

Rectangular mil spec wiring connectors are generally used in military computer systems, radar equipment and communication systems. This type of mil spec wiring connector has a large number of contacts and can transmit more power and signals.

3. Board-to-Board Connectors

Board-to-board mil spec wiring connectors are mainly used for connection between two circuit boards, especially in applications with miniaturization and high density requirements. Its main features are compact design and reliable electrical connection.

4. Power Connectors

Military power connectors are designed for power transmission and usually use larger contact points, which can carry larger current loads and ensure stable operation of equipment under high power conditions.

5. Fiber Optic Connectors

With the development of information warfare, fiber optic communication has gradually been widely used in military communications. The use of fiber optic mil spec wiring connectors in the military field has increased, with the advantages of high-speed data transmission and anti-electromagnetic interference.

6. Micro Connectors

Micro mil spec wiring connectors are small and precise, suitable for space-constrained equipment such as small satellites, drones, etc. This type of connector can usually maintain high reliability under extreme temperature, high humidity and strong vibration conditions.

How to identify mil spec connectors?

The methods for identifying mil spec connectors mainly include the following aspects:

1. Check the model and standard identification

Mil spec connectors usually have clear standard numbers, such as "MIL-DTL-38999", "MIL-DTL-5015", etc., and the model naming rules also strictly follow military standards. For example:

● 38999 series mil spec wiring connectors: generally marked in the form of "D38999/XX-XXXX", which contains information such as shell size, contact type, plug/socket type, etc.

● 5015 series mil spec wiring connectors: usually marked as "MS3102A-XX", where MS3102A represents that it complies with the MIL-DTL-5015 standard, and XX is the specific size code.

If there is a clear MIL standard identification on the connector, it can be basically determined that it belongs to mil spec connectors.

2. Check the appearance and material

Mil spec connectors usually use a solid metal shell, such as aluminum alloy or stainless steel, and are anodized or nickel-plated to enhance corrosion resistance. In addition, the seals of mil spec wiring connectors are usually made of silicone or fluororubber to improve high and low temperature resistance and sealing performance.

3. Measuring electrical performance

The electrical performance of mil spec wiring connectors generally includes:

● Rated voltage and current

● Insulation resistance (usually above 500MΩ)

● Contact resistance (below 5mΩ)

● Withstand voltage test (such as 1000V AC)

If the detected electrical parameters are consistent with military standards, it means that the connector may be a military specification product.

4. Test environment adaptability

mil spec connectors should be able to withstand the following environmental tests:

● Temperature test: adapt to environments with temperatures from -55°C to +125°C or even higher.

● Vibration test: comply with MIL-STD-202 or MIL-STD-810 standards to ensure that the connection remains stable under severe vibration conditions.

● Salt spray test: no obvious corrosion after being exposed to 5% salt spray for more than 48 hours.

● Waterproof test: Many mil spec connectors have IP67/IP68 protection levels and can be immersed in water for a certain period of time without being affected.

5. Supplier and certification information

Mil spec connectors are usually produced by specific authorized suppliers, such as TE Connectivity, Amphenol, ITT Cannon, etc. The products of these manufacturers usually meet military standards and provide certification documents, such as CAGE Code (Merchant Code), NSN (National Stock Number), etc.

LINKHIVE has been leading the connector manufacturing industry since 2010. With a focus on innovation and quality, we offer over 2,000 standard products and customized connector solutions. Our product portfolio includes Mil Spec Connectors, coaxial connectors, and high-quality molded cable assemblies that cater to industries such as automotive, military, and medical devices. As a leading supplier, we pride ourselves on providing affordable, high-quality solutions. Enjoy competitive pricing and prompt delivery when you choose LINKHIVE as your supplier.