Basic Knowledge of Aviation Plugs

Aviation plugs are mainly like bayonet connector, hr 10 compatible with Hirose Connector ,Fluidic/Pneumatic-Electric Hybrid Connector, circular push pull connector, and can also be called circular connectors, more specifically cylindrical pin electrical connectors.

A typical aviation plug contains contacts for transmitting data and power; the name of the aviation plug comes from the military aircraft manufacturing industry in the 1930s.

Currently, aviation plugs are used not only in military equipment and manufacturing, but also in medical equipment, automation, railway transportation and other operating environments where reliability is critical.

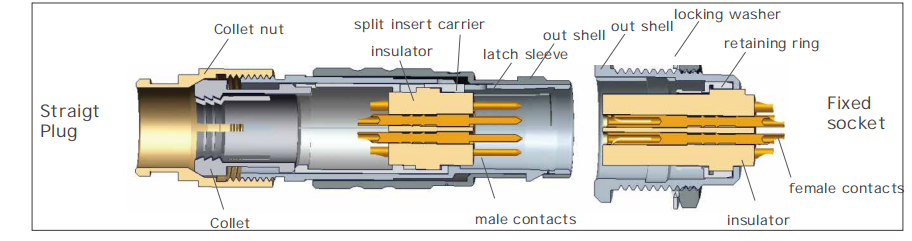

Basic features and components of aviation plugs Aviation plugs usually have a plastic or metal shell around the contacts, which is embedded in an insulating material to keep them aligned. These terminals are usually paired with cables, and this structure makes them particularly resistant to environmental interference and accidental decoupling.

Classification of aviation plugs

1. Classify aviation plugs by the number of pins (number of pins, number of cores). Usually, each terminal of an aviation plug has three, six or eight pins (number of pins, number of cores).

2. Differentiate aviation plugs based on manufacturing specifications, size, connection angle, and connection and disconnection modes. Standards foe aviation plugs: Standard aviation plugs usually refer to those that are designed to comply with German national standards or US military standards (US military standards).

3. According to the size, it can be divided into micro and small aviation plugs.

K Series

multipole socket

multipole plug

socket

German standard aviation plug DIN standard (Deutsches Institut fur Normung, German national standardization agency): DIN aviation plug complies with German electrical standards.

DIN standards include high-frequency capabilities and iconic features such as protective metal shells and round terminals with notches. This construction ensures they are paired with the correct mate.

MIL-Spec connectors: Manufacturers design MIL-Spec connectors based on best practices for military and aerospace applications. These rugged connectors are ideal for high-impact use and are highly resistant to extreme environments.

Some MIL connectors are actually sealed or hermetic due to a strong epoxy seal around the terminals, and most MIL connectors are waterproof. Micro or Nano: Micro- and nano-miniature aviation plugs have smaller pin and hole diameters and more closely spaced contacts.

This structure helps save surface space on the terminal surface and reduces the additional weight of the connector to the assembly.

Aviation plug terminal connection method like most types of electrical connectors, aviation plugs have a variety of termination types. The terminal type you choose determines the nature of the connection between the electrical contacts in each connector assembly.

Options vary by cost, ease of connection and disconnection, and protection against tampering, wear, and environmental damage. The main interface types are insulation displacement, solder, wire wrap, screw or lug, and crimp.

Depending on the specific purpose of the connection, circular aviation plugs have a variety of contact sizes and shell size, and the diameter can be measured. Sensors and other precision and high-sensitivity applications are typical application areas for aviation plugs with smaller shell diameters; larger shell diameters are more suitable for transmitting power, such as in agricultural machinery.

Advantages and disadvantages of circular aviation plugs (compared with rectangular connectors)

Advantages: Circular aviation plugs are ideal for applications that require an electrical connector with a more robust terminal. Their cylindrical shape makes them particularly resistant to mechanical turbulence and impact damage.

Disadvantages: The circular aviation plug surface area limits the arrangement of pins and sockets on the aviation plug surface; while the rectangular connector can install more contacts with larger and uniform spacing on a smaller surface area.