Indian Customers Visit LinkHive Factory and Launch Custom Projects for Endoscopic Cable and Waterproof B Series Connectors

Strengthening Global Cooperation Through Precision Engineering

Dongguan LinkHive Connectors Co., Ltd. proudly announces the successful visit of an Indian customer delegation following our participation in the recent international exhibition. This visit marked another step forward in deepening cooperation and technical exchange between LinkHive and our overseas partners.

The customers’ visit focused on exploring our manufacturing capacity for medical connectors, endoscopic cables, and waterproof circular connector customization. During their factory tour, they visited our CNC machining workshop, connector assembly workshop, and wire harness production area, gaining firsthand insights into LinkHive’s high-precision production system and rigorous quality standards.

After the comprehensive visit, the Indian clients expressed strong confidence in LinkHive’s capabilities and confirmed two customized development projects:

Endoscopic silicone cable assembly — designed for high-definition medical imaging.

Waterproof & dustproof B Series connector upgrade — equipped with a sealed tail cap and protective dust cover.

These projects reflect LinkHive’s dedication to delivering customized, high-performance connection solutions for global medical equipment manufacturers.

CNC Machining Workshop — The Foundation of Precision Manufacturing

The factory visit began in our CNC machining workshop, where the customers observed the meticulous process of producing connector shells, collets, and locking parts.

LinkHive operates 8 CNC lathes (3 horizontal and 5 vertical), ensuring ultra-precise machining with tolerances controlled within ±0.01 mm. Every metallic component—be it brass, stainless steel, or aluminum alloy—undergoes multiple finishing processes, including chrome plating, nickel plating, and anodizing, to guarantee corrosion resistance and longevity.

Our engineers demonstrated how each part transitions from raw bar stock to a mirror-finished component, ensuring perfect compatibility with mating interfaces. The customers were especially impressed by the precision of miniature push pull circular housings, essential for endoscopic and diagnostic applications.

“The surface finish and accuracy are truly at international level,” one of the visitors commented.

“It’s not just about machinery—it’s about craftsmanship and discipline.”

Connector Assembly Workshop — From Components to Perfection

Next, the delegation visited the connector assembly workshop, where all push pull circular connectors are assembled under a controlled clean environment.

The customers watched as our technicians assembled connector components by hand—aligning insulators, inserting contacts, pressing half-shells, and tightening collets. Every part follows a standard process flow that ensures consistent mechanical strength and electrical reliability.

Quality Control Procedures:

Visual inspection for surface defects and deformation

Contact retention and mating endurance testing

Electrical continuity and insulation resistance verification

1000-hour salt-spray corrosion testing

We emphasized that our push pull connectors—compatible with LEMO and ODU series—undergo full testing before shipment. The Indian customers appreciated the robust locking feel of our self-latching design, and noted the connector’s smooth mating and un-mating operation.

Wire Harness Workshop — Integrating Signal, Power, and Flexibility

The third stop was our wire harness workshop, where the clients witnessed the production of custom cable assemblies for medical, industrial, and communication applications.

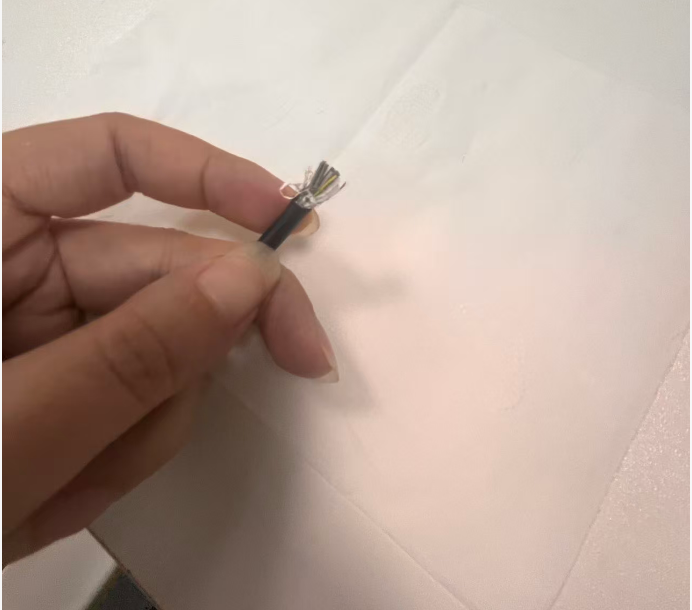

Our engineers presented the customer’s specific project — a medical-grade endoscopic cable with high flexibility and precision shielding structure. This cable is used to transmit HD imaging signals and control data for medical endoscope systems.

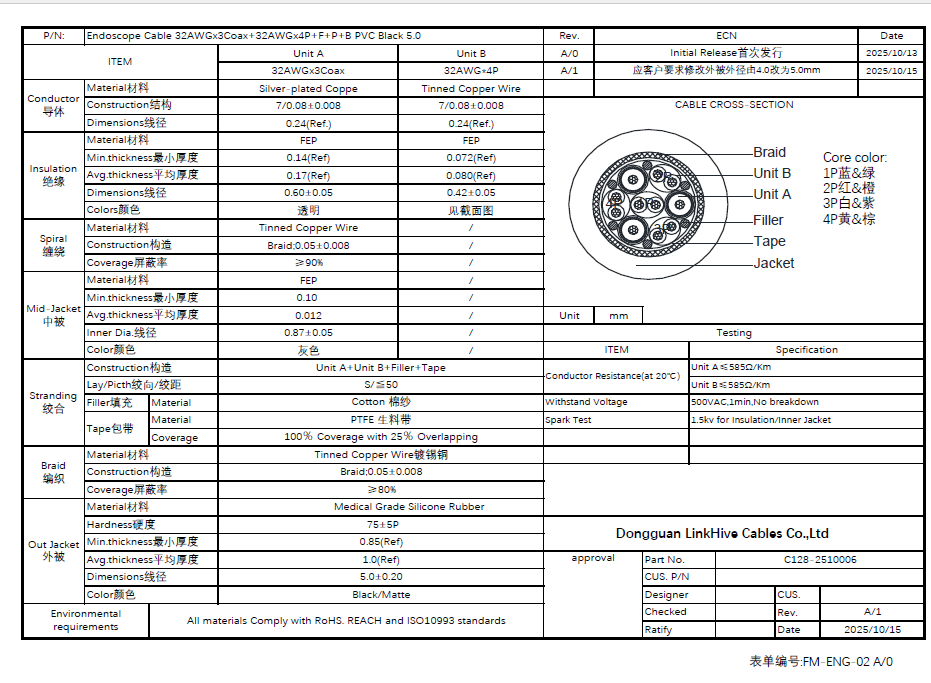

Endoscopic Cable Technical Overview

| Item | Specification |

|---|---|

| Product Name | Endoscope Cable |

| Model | 32AWG×3Coax + 32AWG×4P + F + P + B |

| Outer Diameter | 5.0 mm |

| Conductor | Silver-plated copper (Coax) + Tinned copper (4P) |

| Insulation | FEP transparent |

| Shielding | Spiral tinned copper wire, ≥90% coverage |

| Mid Jacket | Gray FEP |

| Outer Jacket | Black medical-grade silicone rubber |

| Voltage Resistance | 500 VAC / 1 min / No breakdown |

| Spark Test | 1.5 kV for insulation & jacket |

| Temperature Range | -40°C ~ +120°C |

| Compliance | RoHS, REACH, ISO10993 (biocompatibility) |

Cable Features and Advantages

The endoscopic cable was custom-designed according to the client’s exact requirements.

Multi-core hybrid structure: 3 coaxial + 4 signal pairs to support HD video and control transmission simultaneously.

Medical-grade silicone jacket: Ultra-soft, non-yellowing, resistant to sterilization and alcohol disinfection.

High shielding performance: Ensures clear image transmission without interference.

Compact flexibility: The cable remains stable even under continuous bending.

Our R&D team verified every detail — from core color coding to bending strain relief — before finalizing the prototype. The customers approved the design and praised LinkHive’s engineering efficiency and material quality.

Connector Customization — Waterproof & Dustproof B Series Upgrade

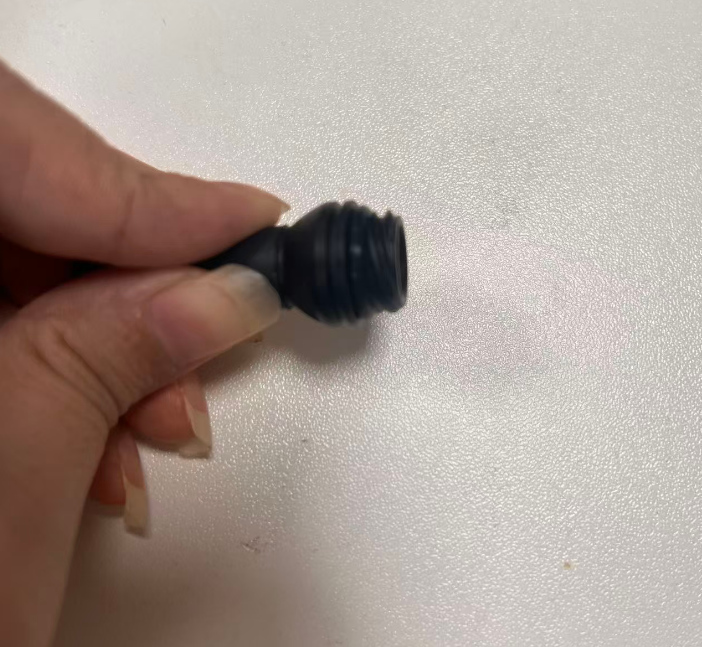

In addition to the endoscopic cable, the Indian customers also requested a customized B Series connector upgrade, requiring enhanced protection for use in more demanding environments.

Our engineers designed a new waterproof tail cap and dustproof cover for the B Series, transforming the standard IP50 connector into an IP68-rated solution while keeping full compatibility with the original push pull locking mechanism.

1. Waterproof Tail Cap (Back Cap)

The back cap is manufactured from black anodized aluminum alloy, ensuring durability and sealing integrity.

It features an integrated silicone O-ring and spiral thread structure, which firmly locks onto the rear housing of the B Series connector.

Specifications:

Material: Aluminum alloy (anodized matte black)

Function: Rear sealing & strain relief

IP Rating: IP68 (mated condition)

Operating Temperature: -55°C ~ +125°C

Compatible Series: LinkHive B Series, LEMO B compatible

This back cap is especially suitable for medical, field-test, and industrial applications where water or dust exposure may occur.

2. Dustproof Cap

For unmated conditions, a black anodized aluminum dust cap was developed to protect both the plug and socket interfaces of the B Series connector.

The dust cap ensures excellent mechanical strength, sealing integrity, and long-term durability even in harsh industrial or medical environments.

It is equipped with an integrated aluminum tether ring, allowing it to remain attached during use, and preventing misplacement during connector handling or sterilization.

The sleek matte black surface not only improves aesthetics but also provides resistance against corrosion, disinfectants, and UV exposure.

Specifications:

Material: Aluminum alloy, anodized matte black

Surface Finish: Sandblasted + anodized coating for corrosion protection

Seal: Precision-machined inner lip and O-ring groove for tight closure

Attachment: Integrated aluminum tether ring

Protection Level: IP68 (mated or capped)

Resistance: Chemical, disinfectant, and UV aging resistant

Application: Protection of plug and socket interfaces during storage, sterilization, or outdoor exposure

3. Comparison Before and After Customization

| Feature | Standard B Series | Customized Waterproof Version |

|---|---|---|

| Rear Cap | None | Sealed aluminum back cap |

| Dust Cover | Optional | Silicone dustproof cover |

| IP Rating | IP50 | IP68 |

| Appearance | Chrome-plated silver | Two-tone silver/black |

| Function | Indoor use | Sterilizable & outdoor compatible |

By combining the metal tail cap and silicone dust cover, the LinkHive B Series now achieves a perfect balance between functionality, aesthetics, and protection — extending its usability to medical sterilization environments, laboratory setups, and portable field equipment.

Product Integration — Cable + Connector Assembly

For the final configuration, our engineering team integrated the custom endoscopic cable with the waterproof B Series connector to create a complete medical assembly.

Each unit underwent:

High-voltage insulation testing (500 VAC)

Water ingress test (IP68)

Mechanical pull test for strain relief

Visual inspection and spark test

The result was a professional-grade assembly with stable signal transmission, perfect flexibility, and a clean visual appearance suitable for medical imaging systems and surgical devices.

Customer Feedback and Partnership Outlook

The Indian customers expressed their satisfaction with the tour and the prototypes.

They highlighted:

High transparency in production process

Excellent connector quality and mechanical fit

Fast customization response and technical communication

Encouraged by the collaboration, both parties signed an initial supply agreement covering connector assemblies, endoscopic cables, and waterproof accessories for future medical projects.

“We are truly impressed with LinkHive’s professionalism and precision. The connectors are robust, and the cables are exceptionally well-made. This partnership gives us confidence to expand our product line,” said the customer representative.

Why Choose LinkHive

15+ Years of Expertise in push pull circular connectors

Full In-house Production — CNC machining, assembly, overmolding, and testing

OEM/ODM Support for custom connector and cable design

Compliance with RoHS, REACH, ISO10993

European Quality, Chinese Cost Efficiency

With continuous innovation, LinkHive aims to become a global leader in precision interconnect systems, offering high-performance solutions across medical, industrial, and defense sectors.

About Dongguan LinkHive Connectors Co., Ltd.

Dongguan LinkHive Connectors Co., Ltd. specializes in the design and manufacturing of push pull circular connectors, custom cable assemblies, and hybrid fluidic connectors.

Our main product lines include:

B Series: Standard push pull connectors for industrial and medical use

K Series: Waterproof push pull connectors (IP68)

P Series: Medical-grade plastic connectors compatible with LEMO REDEL

2C Series: Compact metal connectors compatible with LEMO 2C short

Fluidic/Pneumatic Connectors: For gas and liquid interface applications

Through advanced CNC precision machining, strict assembly control, and 100% product inspection, LinkHive ensures that every connector and cable meets the world’s highest standards of reliability and performance.