In industrial automation, sensor technology, and electrical control systems, connectors play a vital role as an important part of electrical components. They can not only connect various electrical devices, but also ensure the stable transmission of signals and power. M8 connector and M12 connector are two widely used connectors, which show their own advantages and characteristics in different working environments and application scenarios.

Although M8 and M12 connectors look similar, they have significant differences in appearance, size, application areas, and performance. This article will explore the difference between M8 connector and M12 connector in depth and explain their applications in the fields of industry and automation in detail.

M8 and M12 connectors: What are they?

● M8 connector: M8 connector is a circular connector with a diameter of 8 mm, which is commonly used in electrical systems, especially sensors, control equipment, and small mechanical devices. Due to its small appearance, M8 connector is widely used in environments with limited space and small connector size requirements. M8 connector is commonly used in fields such as data transmission, signal transmission, and low-power power supply.

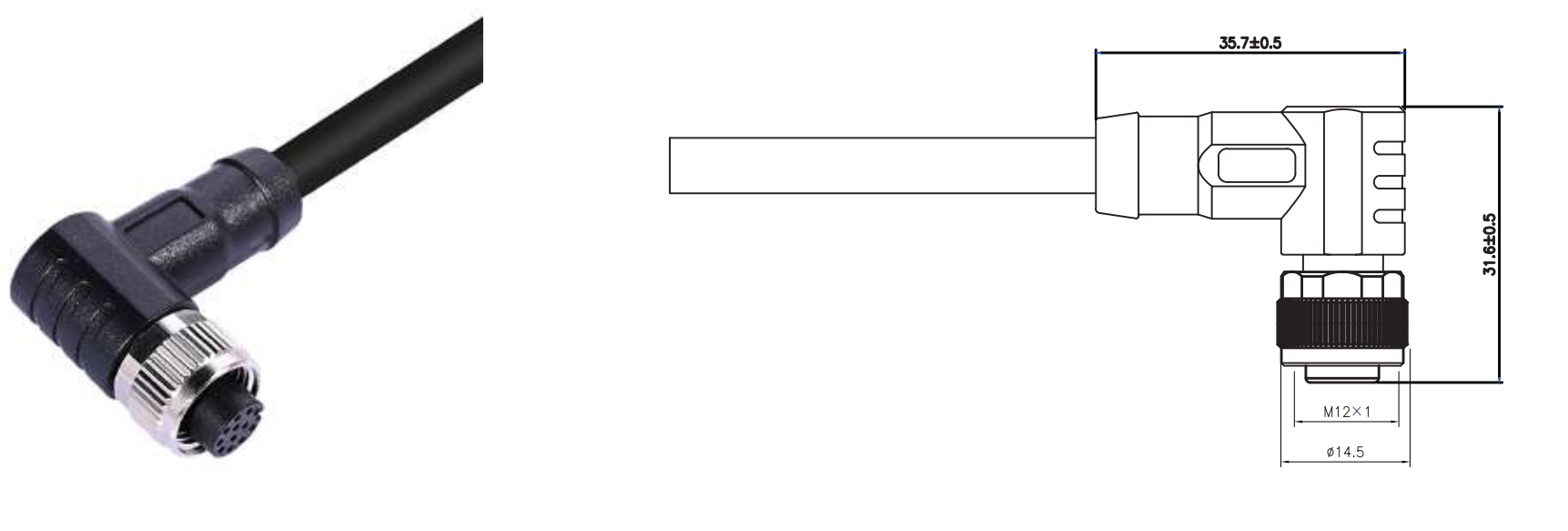

● M12 connector: The M12 connector is a circular connector with a diameter of 12 mm, which is slightly larger than the M8 connector. The M12 connector is usually used for higher power electrical equipment and more complex industrial automation systems. It is designed with higher transmission capacity and greater durability in mind, so it is often used in sensors, industrial control systems, connecting electrical components, etc.

M8 and M12 connectors: What is the difference?

The biggest difference between M8 and M12 connectors: outer diameter size

The most significant difference between the M8 connector and the M12 connector is undoubtedly their outer diameter size. The outer diameter of the M8 connector is 8 mm, while the outer diameter of the M12 connector is 12 mm. This size difference may seem small, but in some applications, the size difference will have a significant impact, especially in applications with limited space. The specific differences are as follows:

1. The space occupied by the outer diameter difference: Since the outer diameter of the M12 connector is larger than that of the M8 connector, the M12 connector will occupy more space in space-constrained applications. In some equipment, the size difference of the connector may lead to installation space limitations, affecting the design and operation of the equipment. For example, in some small sensors or compact devices, the M8 connector can provide greater flexibility due to its small outer diameter and allow installation in space-constrained situations.

2. The difference in outer diameter affects the ease of operation of the connector: The small size of the M8 connector makes it generally easier to connect and disconnect, especially in applications where the connector needs to be frequently plugged and unplugged. Due to its small diameter, the M8 connector is easier to embed into dense electrical systems, thereby reducing space constraints during operation. On the other hand, the M12 connector, due to its larger outer diameter, provides higher connection stability and current carrying capacity, but its operation may be relatively difficult in space-constrained environments.

Difference between M8 and M12 connectors: electrical performance

In addition to the outer diameter size, there are also certain differences in electrical performance between M8 and M12 connectors, which are mainly reflected in the differences in electrical parameters such as rated current, voltage, and contact resistance:

| Parameters | M8 connector | M12 connector |

| Rated current | 3A-4A (depending on the number of pins) | 4A-16A (depending on the number of pins and specifications) |

| Rated voltage | 30V-60V | 125V-250V |

| Contact resistance | Generally ≤5mΩ | Generally ≤5mΩ |

| Insulation resistance | Usually ≥100MΩ | Usually ≥100MΩ |

In terms of parameters, the M12 connector has a higher rated current and rated voltage, which makes it more suitable for applications requiring high power or longer transmission distances, while the M8 connector is more suitable for low-power, short-distance signal transmission.

1. Current and voltage carrying capacity: Due to its larger size, the M12 connector is able to carry higher current and voltage. Generally, the maximum current range supported by the M12 connector is higher than that of the M8 connector, so the M12 connector has an advantage in devices that require high-power current or higher voltage transmission. The M12 connector can handle more power loads and is suitable for demanding electrical connection tasks.

Although the design of the M8 connector focuses on smallness and compactness, its current carrying capacity is generally low. Therefore, the M8 connector is suitable for low-power devices or those occasions that do not require high current. Its current carrying capacity generally does not exceed 4A, while the M12 connector can support up to 12A or higher current and adapt to higher-load devices.

2. Signal transmission performance: In terms of signal transmission, the M8 and M12 connectors each have their own advantages. Due to its small size, the M8 connector is suitable for tasks that require low-speed data transmission or simple signal transmission, while the M12 connector supports high-speed data transmission and is suitable for complex industrial automation systems and sensor networks. Therefore, the M12 connector is more suitable for applications that require stable signal transmission.

Difference between M8 and M12 connectors: connection method

Although M8 and M12 connectors are usually circular structures and can be connected by threads, they differ in connection methods and standards, which makes them suitable for different industrial environments.

1. Connection method of M8 connector: M8 connector usually adopts threaded connection or quick connection method, which enables it to be installed in a smaller space. M8 connector is usually used in equipment that requires more compact and flexible wiring. Due to its small size, M8 connector usually provides more flexibility and convenience when installing.

2. Connection method of M12 connector: M12 connector generally adopts standard threaded connection method, which can provide more stable and secure connection. Due to its larger outer diameter and stronger electrical performance, M12 connector is often used in equipment that requires higher connection stability, such as industrial controllers, sensor systems, etc. In applications that require higher reliability of electrical connections, the advantages of M12 connector are particularly obvious.

Difference between M8 and M12 connectors: durability

Efficient connectors not only need to meet electrical performance requirements, but also need to be able to adapt to various harsh working environments. M8 connector and M12 connector have their own advantages in environmental adaptability and durability, as shown below:

1. Durability of M8 connector: Due to its compact structure, M8 connector performs particularly well in environments with limited size. They are usually designed to be waterproof and dustproof, and can work stably in harsh environments. M8 connectors are usually suitable for indoor environments, especially in automation control and mechanical equipment, because these environments usually do not require extremely high durability.

2. Durability of M12 connector: The durability of M12 connector is usually better than that of M8 connector, especially in environments that need to withstand high mechanical shock, vibration and bad weather. M12 connector not only has stronger waterproof and dustproof capabilities (usually reaching IP67 and above standards), but also can withstand greater mechanical stress, so it is often used in high-demand environments such as factory automation, transportation, and energy.

Difference between M8 and M12 connectors: Application areas

Due to the differences in size, electrical performance, connection method, and environmental adaptability between M8 and M12 connectors, their performance in specific applications is also different.

1. Application of M8 connector: Due to its compact design and low power transmission capability, M8 connector is widely used in sensors, industrial automation, mechanical equipment and other applications with strict space requirements. They are usually used in smaller devices to help achieve simple signal and data transmission.

2. Application of M12 connector: M12 connector is used in more complex and demanding industrial equipment. Due to its ability to carry higher current and voltage, M12 connector is often used in automation control systems, robots, intelligent transportation, power equipment, building facilities and other fields. They are suitable for use in environments that require stable power transmission and signal transmission, especially in extreme environments such as high vibration, high temperature and high humidity.

Buy M8 M12 Connectors at Discount Prices – Factory Direct

If you need electrical connectors at factory prices, LINKHIVE is your go-to supplier! We are a leading China-based company offering wholesale, customized solutions, and bulk purchasing options. From RF coaxial connectors to high-voltage and waterproof connectors, our products are used in medical, telecom, aerospace, and industrial applications. Looking for cheap but high-quality solutions? Get exclusive discounts, promotions, and quotes today!