Electrical connectors play a vital role in many fields such as modern industry, communications, automobiles, aerospace, marine engineering and outdoor electronic equipment. Although ordinary electrical connectors can achieve efficient transmission of electrical signals or electrical energy, they may cause short circuits, signal interference and even equipment damage due to moisture intrusion in humid, high humidity, rain or other liquid environments.

Therefore, in order to ensure the stability and safety of electrical connections, water tight electrical connectors came into being. This article will introduce the definition, structure, working principle, common protection level, application field and key points of waterproof technology of water tight electrical connectors in detail.

What is a waterproof electrical connector?

A waterproof electrical connector is an electrical connection component specially designed to prevent water, liquid, moisture, etc. from entering the interior of the connector. Its key function is to protect electrical contacts from moisture or other liquids, thereby ensuring that the equipment can work properly in humid, harsh or humid environments. Waterproof connectors are widely used in electronic equipment that may be exposed to water, rain, steam, corrosive liquids or liquid contamination.

The design of water tight electrical connectors usually involves high sealing performance to prevent moisture from entering the contact part of the connector while ensuring good electrical conductivity. Its protection capability is usually expressed by "IP (Ingress Protection) level". The higher the IP level, the stronger the protection capability of the connector against moisture and solid objects. For example, IP67 is equivalent to a connector that is completely protected from moisture intrusion, while IP68 means that it can withstand longer periods of immersion in water.

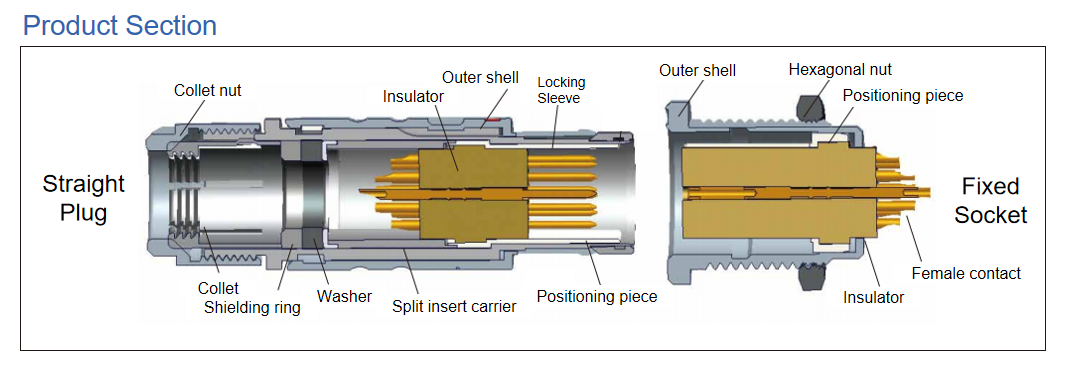

Structure of waterproof electrical connector

● Shell: The shell part is usually made of high-strength plastic or metal materials, such as aluminum alloy, brass or stainless steel, which has good corrosion resistance and mechanical strength, and can effectively protect the connector from the influence of the external environment.

● Seal: One of the core parts of the water tight electrical connector is the sealing ring. The sealing ring is usually made of rubber or silicone to provide sealing protection between the plug and the socket. Common sealing designs include O-rings, gaskets, etc. These seals ensure that the connector can maintain a good sealing effect during the plug-in and unplug process.

● Contact point: The contact point is an important part of the electrical connector, usually made of highly conductive metal such as copper or gold-plated copper. In the water tight electrical connector, the contact point also needs to have corrosion resistance to ensure stable electrical transmission even in a humid environment.

● Locking mechanism: Waterproof electrical connectors are usually equipped with locking devices, such as rotating locks, bayonet locks or threaded locks, to ensure that the connector does not loosen or fall off during the plugging and unplugging process. This locking mechanism effectively prevents the ingress of moisture and dust, and also prevents the connector from falling off during operation.

Working principle of waterproof electrical connector

The working principle of water tight electrical connector is similar to that of ordinary electrical connectors, transmitting current or signals through the electrical contact points between the plug and the socket. However, the key to the working principle of water tight electrical connector is its sealing design, which can prevent water, moisture and other liquids from entering the connector. The waterproof ability of each connector is usually measured according to its IP rating. Waterproof electrical connectors are generally designed with waterproof seals, locking mechanisms and dustproof designs to ensure that they can maintain reliable electrical connections even in extreme weather conditions.

What is the protection level of waterproof electrical connectors?

The protection performance of water tight electrical connectors is usually measured by the international standard IP (Ingress Protection) level. The IP rating consists of "IP" + two digits:

The first digit (dustproof rating): indicates the protection against solid particles (such as dust);

The second digit (waterproof rating): indicates the protection against water.

Common IP ratings and their meanings:

| IP rating | Dustproof | Waterproof |

| IP65 | Completely protected from dust ingress | Protected from water splashes |

| IP66 | Completely prevent dust intrusion | Protect against strong water flow |

| IP67 | Completely protected from dust ingress | Can be immersed in 1 meter of water for a short period of time |

| IP68 | Completely prevent dust intrusion | Can be immersed in water of a certain depth for a long time |

| IP69K | Completely prevent dust intrusion | Can withstand high temperature and high pressure water washing |

For example:

IP67 waterproof electrical connector is suitable for outdoor equipment and can be immersed in water for a short time without affecting its function.

IP68 waterproof electrical connector is suitable for equipment that works underwater for a long time, such as marine detection equipment or underwater lighting systems.

IP69K waterproof electrical connector is suitable for equipment that requires high pressure and high temperature flushing, such as food processing and pharmaceutical production.

What are the types of waterproof electrical connectors?

According to different needs, there are many types of waterproof electrical connectors, the common ones are:

1. Round waterproof electrical connector

2. Square waterproof electrical connector

3. Sealed cable connector

4. Outdoor waterproof electrical connector

1. Round waterproof electrical connector

The round water tight electrical connector is the most common type of waterproof connector. It has a compact design and is usually composed of a metal or plastic shell and a waterproof seal. This type of connector is widely used in industrial automation, communications, and military fields. Its waterproof performance usually reaches IP67 or higher, and can prevent the intrusion of external substances such as water, dust, and oil.

2. Square waterproof electrical connector

Compared with circular connectors, square water tight electrical connectors have a larger contact surface and stronger anti-interference ability. This type of connector is mostly used for equipment that requires large current transmission, usually in automobiles, power equipment, and industrial fields that require high-strength connections. The sealing and durability of square water tight electrical connectors are usually high, and they are suitable for various complex environments.

3. Sealed cable connectors

Sealed cable connectors are usually used for connection with cable ends. Their shell design has a good sealing function and can effectively prevent the infiltration of moisture and chemicals. This type of connector is commonly found in underwater equipment, marine engineering equipment, and other humid environments, and can ensure the reliable operation of equipment in long-term immersion in water or high humidity environments.

4. Outdoor waterproof electrical connector

Outdoor water tight electrical connectors are generally used for equipment exposed to outdoor environments, especially equipment that needs to operate in rainy and snowy weather or extreme temperatures. They are not only highly waterproof, but also can withstand high temperature differences to prevent poor contact or degradation of electrical performance due to temperature changes. Such connectors are widely used in equipment such as agricultural equipment, construction equipment, and traffic lights.

Buy waterproof electrical connectorss – LINKHIVE Factory Wholesale

Looking for water tight electrical connectors at factory prices? LINKHIVE is a China-based manufacturer offering tailor-made solutions for medical, industrial, and telecom applications. With a 3,000 sqm production facility and 100+ skilled professionals, we provide bulk supply, wholesale prices, and special promotions on push-pull connectors, RF coaxial connectors, and high-voltage connectors!