In the fields of electronics, electrical, communications and industry, connectors are key components for achieving electrical and mechanical connections. There are many types of connectors, among which thread connectors are a common connection method and are widely used in many industries due to their excellent stability, reliability and durability. The core feature of thread connectors is that they achieve connection by tightening the threads, thereby ensuring a firm connection between the devices at both ends.

This article will explore in depth "What are thread connectors", and analyze in detail their working principles, structural characteristics, application scenarios, advantages and their important roles in different fields.

What is a thread connector?

A thread connector is a connector that is connected to each other through threads. Threaded BNC connectors usually consist of a plug and a socket. The plug part has an external thread, while the socket part has a matching internal thread. By rotating the plug, the external thread and the internal thread are tightly combined to achieve a stable electrical or mechanical connection.

When thread connectors are connected, their unique thread design ensures the firmness of the connector, which can not only withstand high mechanical stress, but also has strong vibration resistance. In addition, the threaded BNC connector also has waterproof and dustproof properties, and can work stably in harsh environments. Therefore, it has been widely used in many industries.

How does thread connectors work?

The working principle of thread connectors is simple and efficient. The connection process is achieved through the threaded fit of the plug and the socket. The specific steps are as follows:

● Plug and socket fit: The plug of the threaded BNC connector usually has external threads, while the socket has internal threads. During the connection process, the threads of the plug and the socket begin to screw together by docking.

● Tightening: By rotating the plug, the external and internal threads are tightly combined. As the rotation proceeds, the contact between the plug and the socket gradually increases, and the connection becomes more secure.

● Locking connection: When the threads of the plug and the socket are fully tightened, the connection is completed, and a stable electrical or mechanical connection is formed between the plug and the socket. At this time, the contact points in the connector are in good contact, and the signal or current can be transmitted smoothly.

● Disconnection: When disconnecting, the reverse rotation of the plug can loosen the thread from the socket, thereby disconnecting.

Through this simple and efficient connection method, the threaded BNC connector can ensure that the connector always remains firm and stable in the application, and has strong anti-interference ability.

What are the structural components of thread connectors?

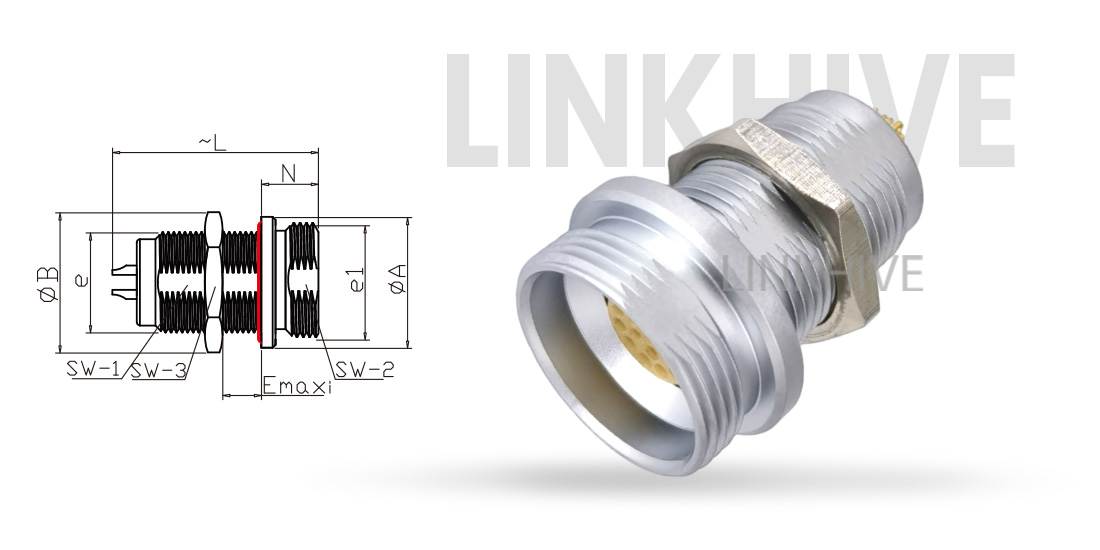

The structure of the threaded BNC connector is relatively simple, mainly consisting of the following parts:

● Shell: The shell is usually made of metal or plastic materials to protect the internal contact points of the connector and other electronic components. The shell also plays a protective role to a certain extent, preventing dust, moisture or other corrosive substances in the environment from entering the connector.

● Contact element: The contact element is the most important part of the connector, responsible for transmitting current, signals or data. These contact elements are usually made of highly conductive materials (such as copper alloys, gold-plated or silver-plated materials) to ensure stable electrical performance.

● Threaded part: The threaded part is the key part of the threaded BNC connectors, responsible for achieving a tight connection between the plug and the socket. The design of the thread is very important, it not only ensures a firm connection, but also ensures smooth plugging and unplugging operations.

● Sealing device: In some special environments, threaded BNC connectors will also add sealing devices, such as O-rings, washers, etc., to prevent moisture, dust, etc. from entering the connector. These sealing devices can improve the protection level of the connector and maintain stable performance in harsh environments.

● Anti-vibration design: Some threaded BNC connectors will also add anti-vibration design, such as by adding anti-vibration locks on the outside of the connector, or performing special treatment on the internal and external threads of the connector to improve its ability to resist vibration.

What are the advantages of thread connectors?

As a common connection method, thread connectors have many unique advantages, which have made them widely used in many fields. The following are the main advantages of thread connectors:

1. High connection stability

Since thread connectors are connected by screwing together, this design makes the connection very stable. Once tightened, the connector will be firmly fixed and can withstand large mechanical loads or vibrations, greatly improving the reliability of the connection.

2. Adapt to harsh environments

Thread connectors have strong anti-vibration capabilities and can still maintain a relatively stable connection in high temperature, humidity, vibration and other environments. In addition, many thread connectors are also designed with waterproof and dustproof sealing devices, which can effectively prevent moisture, dust or other corrosive substances from entering the inside of the connector, ensuring its normal operation in harsh environments.

3. Easy to operate and maintain

The operation of thread connectors is very simple, and the connection and disconnection can be completed by rotating the plug. This simple operation method not only reduces the complexity of operation during use, but also improves the maintenance efficiency of the equipment. When the connector fails or needs to be replaced, the operator only needs to rotate to quickly disconnect the connection for maintenance or replacement.

4. Strong durability

Threaded BNC connectors are usually made of metal or other durable materials with strong corrosion resistance and wear resistance. This enables threaded BNC connectors to maintain stable performance over long periods of use and reduce the frequency of maintenance and replacement.

5. Good electrical performance

The contact elements of threaded BNC connectors are usually made of highly conductive materials such as copper alloys, gold-plated or silver-plated materials, which ensures the stability of their electrical performance. This makes thread connectors not only suitable for mechanical connections, but also for electrical connections, and are widely used in industries such as electronics, communications and power.

What are the application areas of thread connectors?

Due to their unique design and reliable performance, thread connectors have been widely used in many fields. The following are some common application areas of thread connectors:

1. Military and aerospace fields

In the military and aerospace fields, the stability and durability of thread connectors are their important characteristics. Under high temperature, strong vibration or extreme environmental conditions, threaded BNC connectors can ensure reliable connection between devices, so they are widely used in high-tech equipment such as fighter jets, missiles, satellites, etc.

2. Industrial automation

In industrial automation, thread connectors are widely used in various industrial equipment such as sensors, robot control systems, and monitoring equipment. Since these devices often need to operate in harsh working environments, the anti-vibration, waterproof, and dustproof characteristics of thread connectors have made them widely used in these fields.

3. Automobile industry

Threaded BNC connectors are also widely used in the automotive industry. Especially in the new automotive fields such as electric vehicles and smart cars, threaded BNC connectors play an important role in high-voltage battery systems, electrical control systems, and sensors and other equipment.

4. Communications industry

In the communications industry, thread connectors are used for electrical connections to transmit signals and data. Especially in the fields of high-speed data transmission systems, optical fiber communications, radio communications, etc., thread connectors can ensure the stability and security of signal transmission.

5. Medical equipment

In medical equipment, thread connectors are used to connect various instruments, sensors, power modules, etc. These devices usually require high-precision electrical connections and often need to work in humid or corrosive environments, so the waterproof, corrosion-resistant and reliability of thread connectors make them an ideal choice.

How to choose the right thread connectors

When choosing threaded BNC connectors, it must be determined according to the specific application requirements. The following are several key factors to consider when choosing thread connectors:

1. Connector size and specifications

Choose threaded BNC connectors of appropriate size and specifications according to the design size and requirements of the equipment. Threaded BNC connectors come in a variety of different sizes and types, such as M series, NPT series, etc., which must be selected according to the actual use environment.

2. Working environment

Choose thread connectors suitable for the working environment. For high temperature, high humidity or highly corrosive environments, thread connectors with protective functions should be selected to ensure that the connectors can work properly in these environments.

3. Electrical performance

According to the electrical requirements of the connector, select suitable contact materials and electrical performance indicators. If you need to transmit large currents or high-speed signals, you should choose connectors made of materials with higher conductivity.

4. Durability and maintainability

According to the frequency of use and maintenance requirements of the equipment, choose threaded BNC connectors that are durable and easy to maintain. High-quality thread connectors can withstand longer use and reduce the frequency of maintenance and replacement.

LINKHIVE is a trusted manufacturer of precision connectors, offering over 2,000 standard products and a wide range of custom solutions. With more than a decade of experience, our products are engineered to meet the highest quality standards. Whether you need connectors for military, aerospace, or telecommunications applications, we have the right solution. Our factory in Dongguan, China, ensures cost-effective manufacturing, competitive pricing, and fast turnaround times. Explore our wholesale offers, and contact us today for quotes and customized connector solutions that meet your unique requirements.