As an important electronic component, the connector carries the task of transmitting electrical signals or electricity. Different types of connectors have different design and application requirements, and push-pull connectors are a special type. Among many connector manufacturers, Lemo is a world-renowned connector brand, and its push-pull connectors are known for their high performance and high safety.

This article will conduct an in-depth analysis around the theme of "Is the Lemo push pull connector safe?" to explore its design features, working principles, application areas, and safety assurance.

What is the Lemo push pull connector?

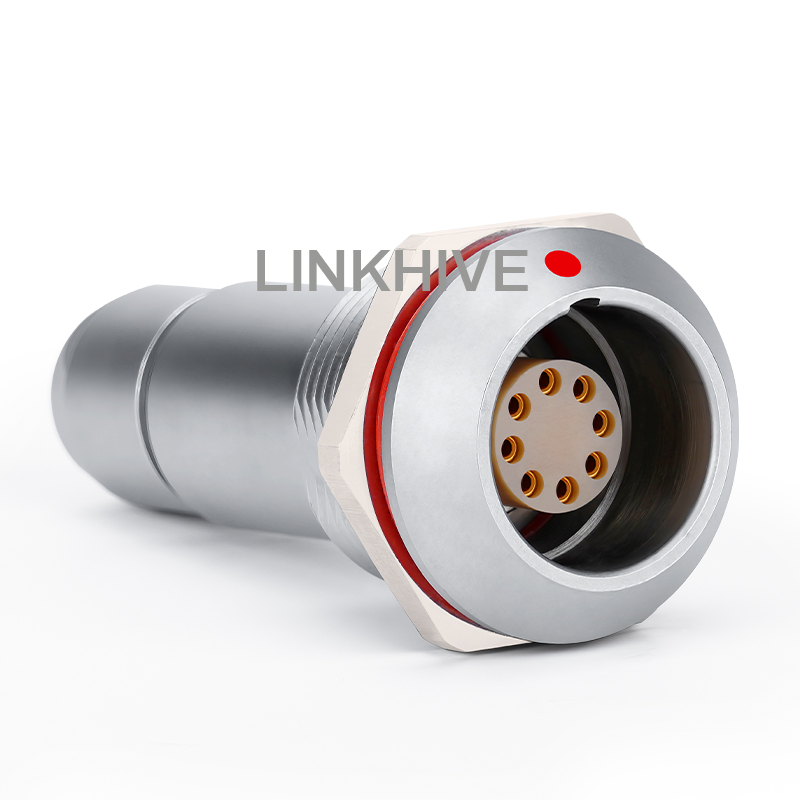

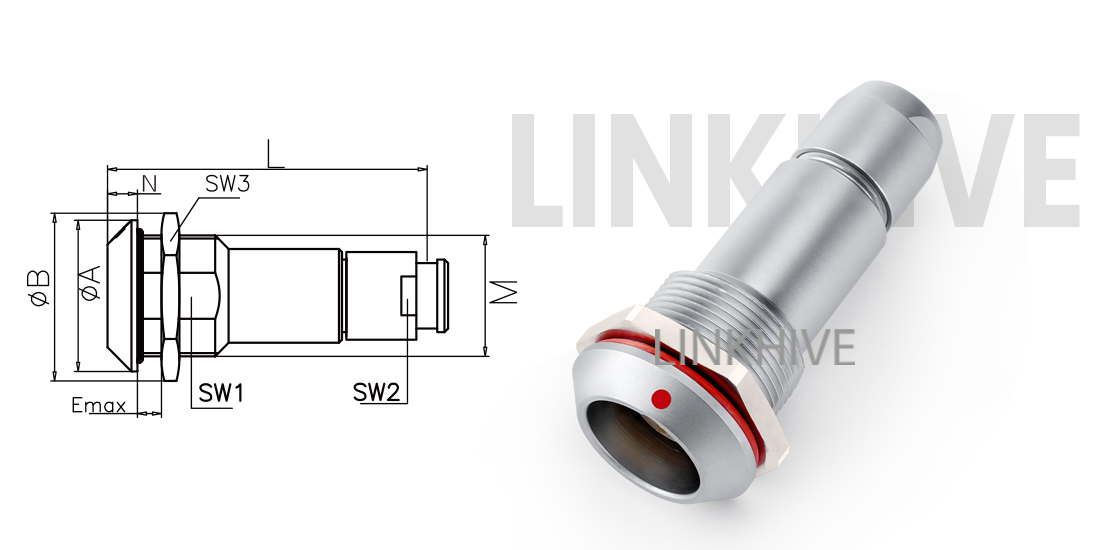

The Lemo push pull connector is an electrical connector that connects and disconnects through push-pull actions. Its most notable feature is that it can be connected or disassembled through a simple push-pull operation, which greatly improves the convenience and efficiency of use. The Lemo push pull connector is often used in high-demand application scenarios, especially in medical equipment, industrial automation, broadcast communications, aerospace and other fields.

The Lemo push pull connector usually has a precise contact structure and sealing design to ensure high reliability and high performance. In the design of the connector, Lemo pays special attention to the protection and sealing functions to prevent the influence of external environmental factors such as moisture and dust, and ensure the stability and long-term service life of the equipment.

What safety designs does the Lemo push pull connector have?

Mechanical safety

The mechanical design of the Lemo push pull connector pays great attention to safety. Its housing is usually made of high-strength metal materials or durable plastics to ensure the stability and firmness of the connector when connected or disconnected. The push and pull action of the connector requires a certain amount of force, and the design ensures that the contact between the plug and the socket will not be easily loosened. This reliable mechanical design not only ensures stability during use, but also effectively avoids electrical failures caused by accidental disconnection.

In addition, the plug and pull operation of the Lemo push pull connector is usually equipped with an anti-misoperation mechanism. Even in harsh environments such as high vibration and high temperature, the connector can ensure firm contact and avoid safety hazards caused by improper operations such as misplugging or reverse plugging.

Electrical safety

Electrical safety is one of the most critical factors in all electrical connectors. The design of the Lemo push pull connector focuses on reducing the occurrence of electrical failures such as arcing, overload, and poor contact. On the contact surface of the plug and socket, Lemo uses highly conductive and wear-resistant materials to ensure the stability and safety of current transmission. In addition, the Lemo push pull connector also has extremely low contact resistance, which reduces heating and electrical failures caused by excessive resistance.

In terms of preventing electrical short circuits and current overloads, Lemo push pull connectors use multiple safety mechanisms, such as built-in fuses, overload protection and other functions. The isolation structure inside the connector effectively prevents internal faults caused by external currents and ensures the electrical safety of the connector.

Sealing performance

The sealing design of the Lemo push pull connector is crucial for safety. Since many applications (such as medical equipment, industrial control systems, etc.) are often faced with humid or harsh environments, waterproof and dustproof functions have become essential features of the Lemo push pull connector. Lemo push pull connectors use sealing technologies such as O-rings and clamps to ensure that they can effectively prevent the intrusion of external environments such as moisture, dust and chemicals.

According to the international protection level standard (IP level), Lemo push pull connectors generally have a higher protection level, such as IP67 or higher. This means that the Lemo push pull connector can withstand a certain degree of water immersion and can still work normally in an environment exposed to dust and moisture for a long time, thereby improving the safety and stability of the equipment in extreme environments.

Fireproof and high temperature resistance

For some special applications such as high temperature and high pressure, Lemo push pull connector also uses high temperature resistant and fireproof materials to cope with harsh working environments. The connector shell is usually made of high temperature resistant materials (such as engineering plastics such as PBT and PA) and is equipped with a high temperature resistant insulation layer to effectively prevent material damage or electrical failure caused by high temperature or fire.

The metal materials (such as copper alloy or gold-plated materials) used in the contact parts inside the push pull connector also have good high temperature resistance and can maintain stable electrical performance under long-term working conditions, thereby ensuring electrical safety in high temperature environments.

Safety guarantee mechanism of Lemo push pull connector

Anti-misinsertion design

The Lemo push pull connector adopts an anti-misinsertion design to ensure that the plug can only be paired with the socket in the correct direction when the connector is inserted. This design effectively prevents poor electrical contact or connector damage caused by incorrect operation and improves the safety of operation.

Self-locking mechanism

Lemo push pull connector usually has a self-locking function, that is, the connector can automatically lock after insertion to prevent the connector from loosening due to vibration or external force. This function is particularly important for applications that require stable connections (such as aviation, medical, etc.), effectively preventing electrical failures or safety accidents caused by looseness.

Corrosion-resistant design

Due to the possibility of chemical corrosion in many industrial environments, Lemo push pull connectors are usually designed with corrosion-resistant materials to ensure that the connector does not reduce its performance due to corrosion during long-term use. Whether in marine environments, chemical plants or other special environments, Lemo push pull connectors can maintain reliability for a long time.

Overload protection

Lemo push pull connectors are designed with an overload protection mechanism for high current applications. When the current in the connector exceeds its rated load, the internal overload protection device can automatically cut off the current to prevent overload from damaging the electrical system. This function is particularly suitable for some high-power devices, ensuring the safety of the connector and the entire electrical system.

Application safety of Lemo push pull connectors

Lemo push pull connectors are widely used in medical, aerospace, broadcasting, industrial automation and other fields, where safety is often the primary consideration. With its high reliability and excellent safety performance, push pull connectors meet the stringent requirements for connectors in these fields.

● Medical field: In medical equipment, Lemo push pull connectors are often used in medical imaging equipment, life support equipment, surgical instruments, etc. Medical equipment requires connectors to have high reliability and electrical safety to ensure that the equipment can operate stably and avoid medical accidents caused by connector failure. The sealing performance, anti-electric shock protection, and corrosion resistance of push pull connectors have greatly improved the safety of medical equipment.

● Aerospace field: Aerospace equipment faces extreme conditions such as high temperature, low temperature, and vibration during use. The high temperature resistance, low temperature resistance, and vibration resistance of Lemo push pull connectors make them important components in this field. Through self-locking design and overload protection functions, push pull connectors can ensure the safe operation of aerospace equipment in complex environments.

● Industrial automation field: In automated production lines, push pull connectors are often used to connect electrical equipment such as sensors and actuators. High-frequency vibration, high humidity, and dust in industrial environments often affect the stability of equipment, while the waterproof and dustproof characteristics and stable electrical connection of Lemo push pull connectors ensure the safety and efficiency of production line equipment.

How safe is the Lemo push pull connector?

Based on the above analysis, Lemo push pull connector performs well in terms of safety:

1. Self-locking structure ensures a stable connection and prevents accidental detachment

2. High-quality materials and precision manufacturing enhance durability and reliability

3. High protection level, suitable for harsh environments

4. Excellent vibration and impact resistance to ensure mechanical safety

5. Strong electromagnetic compatibility to prevent signal interference

Therefore, whether in the fields of medical, aerospace, military, industrial automation or precision instruments, Lemo push pull connector can provide reliable and safe connection solutions to meet demanding application requirements. It can be said that push pull connector is not only safe, but also one of the best choices in high-end connection applications.

LINKHIVE, established in 2010 and headquartered in Dongguan, China, is a leading manufacturer of precision connectors. We specialize in providing over 2,000 custom solutions and cable assemblies designed to meet the specific needs of various industries. With over a decade of innovation, numerous patents, and a 3,000-square-meter factory, we supply high-quality connectors like push-pull connectors, M series circular connectors, and coaxial connectors.