The M12 connector is a common connector in industrial automation, sensor technology, robotics, and other electronic devices. It has been widely used in many fields due to its compact design, high reliability, and good protection performance. As a circular connector, the M12 connector is widely used to transmit power and signals, especially for devices that require high space, reliability, and durability.

When talking about M12 connectors, the number of pins is a very important feature, which directly affects the function and application scenarios of the connector. Different equipment and application requirements determine the number of pins in the M12 connector. Therefore, understanding the pin configuration of the M12 connector and its role is crucial for selection and design.

This article will take a deep look at the number of pins in the M12 connector and how this feature affects its design, performance, and application. Through a detailed analysis of the M12 connector, we can better understand its importance in modern industry and technology.

What is an M12 connector?

The M12 connector is a circular electrical connector that is commonly used in systems such as industrial automation, sensor networks, data communications, robotic control, and mechanical equipment. The M12 connector is named after its external thread diameter of 12 mm. It usually consists of a plug and a socket and can be used for the transmission of power, electrical signals and data.

The M12 connector is compact in design and is usually installed by threaded connection. It has high vibration resistance, corrosion resistance and water resistance. Its standardized design allows it to adapt to various industrial applications while providing good protection, so it can maintain stable performance in harsh environments.

How many pins does the M12 connector have?

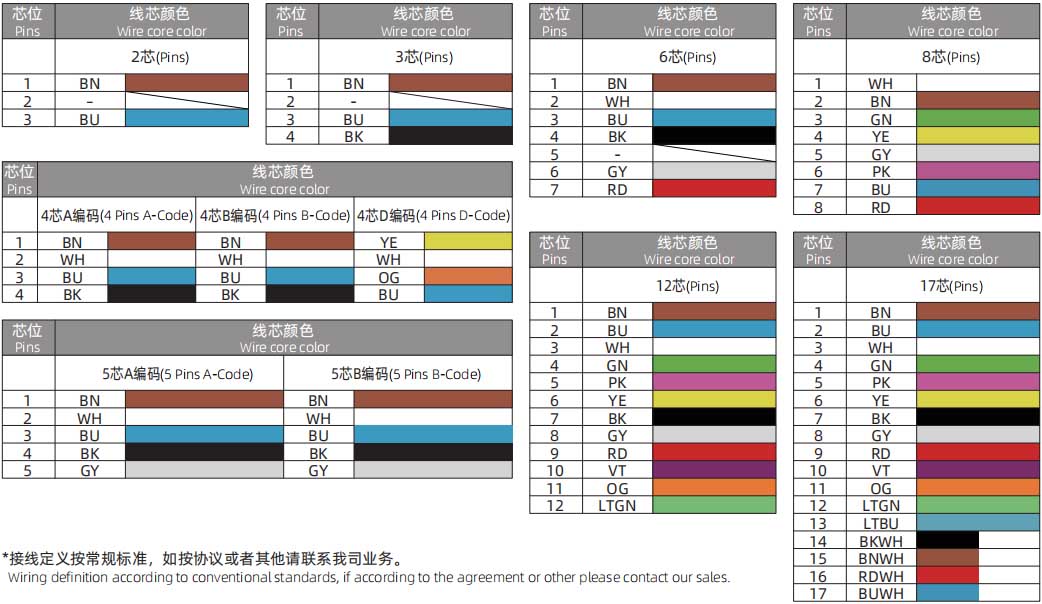

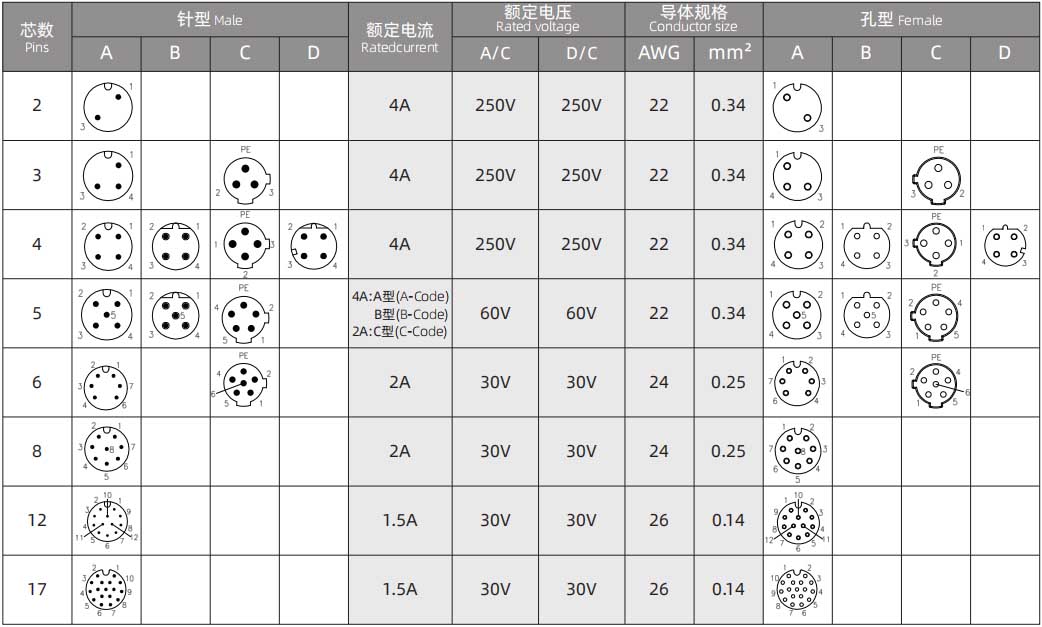

The "number of pins" of an M12 connector refers to the number of metal contacts or terminals inside the connector. Depending on different needs, the number of pins of an M12 connector can range from 2 to 12. M12 connectors with different numbers of pins are suitable for different applications and devices, so it is crucial to understand the pin configuration when selecting an M12 connector.

2-pin M12 connector

The 2-pin M12 connector is usually used for simple power connections or switch signal transmission. The application scenarios of this type of connector generally do not involve complex data communications, but are used for some basic power connections and simple control signal transmission. For example, 2-pin M12 connectors are commonly used in sensors, actuators and other devices for low-power signal transmission.

3-pin M12 connectors

3-pin M12 connectors are widely used in sensors, electric actuators and other devices that require three signal connections. In addition to the power and ground wires, the third pin is usually used for signal transmission, which can support some simple control or sensor feedback.

4-pin M12 connectors

4-pin M12 connectors are generally used for applications with power lines plus two signal lines, which are common in sensors or small actuator devices. 4-pin M12 connectors support more complex signal transmission through additional pins and provide stronger functionality, for example, the ability to transmit two control signals or input and output signals at the same time.

5-pin M12 connectors

5-pin M12 connectors are generally used in applications that require more signal transmission. It is commonly used in industrial automation, robotics and sensor systems. This type of connector can support more control signals or data transmission by increasing the number of pins, allowing the device to perform more complex operations or provide more feedback.

8-pin M12 connector

8-pin M12 connectors are particularly important in some complex applications, such as data acquisition systems, complex sensor networks, and industrial communication equipment. With 8 pins, M12 connectors can handle multiple signal and power transmission tasks at the same time, so they are very suitable for multi-channel data transmission or high-frequency control scenarios.

12-pin M12 connector

12-pin M12 connectors are often used in more complex systems, where more power, signals, and data need to be transmitted simultaneously. In some high-end industrial equipment, robotic systems, and large-scale automation systems, 12-pin connectors can ensure fast and stable electrical connections between devices and support high-frequency data transmission.

Impact of the pin configuration of the M12 connector

The pin configuration of the M12 connector directly affects its function and applicability. Depending on the number of pins, the M12 connector can be divided into the following categories:

Signal transmission

In many applications, M12 connectors are used for signal transmission. Fewer pin configurations (such as 2-pin, 3-pin, and 4-pin) are usually used for the transmission of power and control signals, which are suitable for simple sensors or switch devices. These connectors are mainly used to transmit digital signals or low-frequency analog signals, and the frequency and amount of signal transmission are small.

Data transmission

For applications that require high-speed data transmission, the number of pins of M12 connectors will increase accordingly. For example, 8-pin or 12-pin M12 connectors can support the transmission of multi-channel signals, which is particularly suitable for multi-channel data acquisition systems in industrial automation, sensor networks, and complex equipment. These connectors can handle larger signal bandwidths and more complex data flows, meeting the requirements of industrial equipment for high-speed data communication.

Power supply

For applications that require power supply, M12 connectors are often designed to support the transmission of power, ground, and signal lines. For example, a 4-pin M12 connector usually includes a power line and a signal line, which can provide power to the device and transmit signals. In situations with higher power requirements, such as robot control or industrial equipment, the number of pins of M12 connectors may be higher to meet more complex power and signal transmission requirements.

Multi-function integration

In some high-end applications, M12 connectors need to integrate multiple functions, such as power supply, signal transmission, data communication, etc. At this time, the pin configuration of the M12 connector is usually more (such as 8 pins or 12 pins) to meet the transmission of different signal types and electrical requirements. For example, in industrial automation systems, the multi-pin design of the M12 connector can simultaneously support multiple sensor signals, power inputs, and feedback signals to ensure the efficient operation of the system's multi-channels.

Standardization and selection of M12 connectors

The standardization of M12 connectors is one of the reasons for its widespread application. The standard of M12 connectors not only involves its appearance and structure, but also includes the design of the number of pins. These standards enable M12 connectors produced by different manufacturers to be interchangeable, facilitating the design and maintenance of equipment.

Standardized appearance and size

M12 connectors usually follow industrial standards, and their appearance, size, pin configuration and interface method (for example, threaded connection) are standardized. This allows engineers to easily choose the M12 connector that suits their equipment without worrying about compatibility issues.

Choose the right number of pins

When selecting an M12 connector, designers need to determine the number of pins of the connector based on the needs and usage scenarios of the equipment. If the device needs to transmit multiple signals or high-power current, it is necessary to select a connector with a larger number of pins; if the device only needs a simple power supply or switch signal, select an M12 connector with fewer pins.

Application scenarios and functional requirements

The number of pins of the M12 connector not only affects the number of electrical transmissions, but also determines the functionality of the device. For example, sensor systems usually require fewer pins, while in complex robots or automated control systems, the number of pins of the M12 connector is usually more, which can meet the transmission requirements of power, signals and data at the same time.

For over a decade, LINKHIVE has been providing premium connector solutions for a variety of industries, including telecommunications, medical devices, and aerospace. With over 2,000 standard products and an array of customized connectors, we are the trusted manufacturer of choice. Our connectors are built to meet global standards like ISO9001 and UL, ensuring high-quality and reliable performance. Whether you need connectors for high-pressure, waterproof, or military-grade applications, we offer low prices and customized solutions to meet your specific needs. Get in touch with LINKHIVE today for competitive pricing and excellent service.